01020304

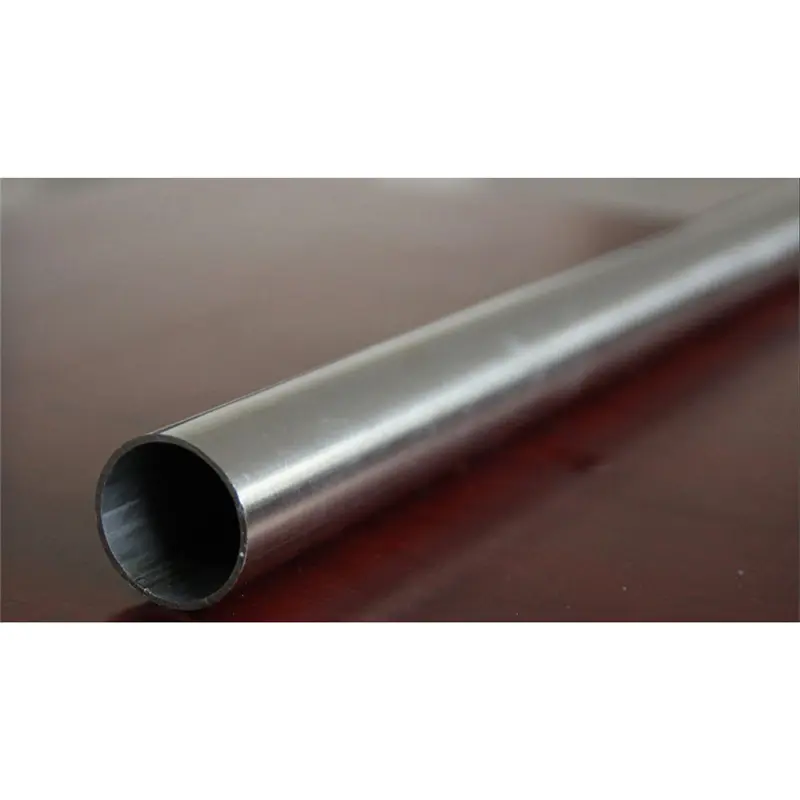

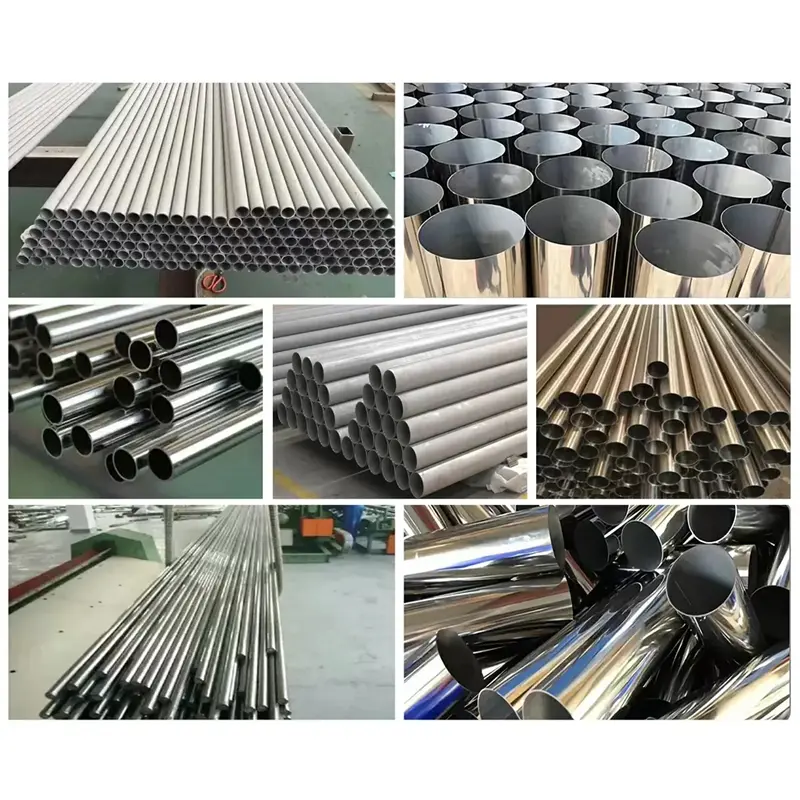

316L stainless steel welded pipe market price

Product Description

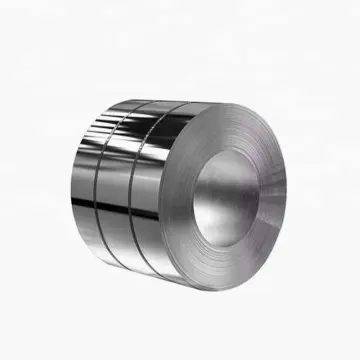

Type: Ferritic, Austenite, Martensite, Duplex

Technology: Cold Rolled and Hot Rolled

Size: According to the customer's requests

Standards: AISI ASTM JIS SUS DIN EN and GB

Certifications: ISO 9001, SGS, BV

Materials

Stainless steel material: Common stainless steel welded pipe materials include 304, 316, 321, etc.

304 Stainless Steel: Offers excellent corrosion resistance and formability, making it suitable for general applications.

316 Stainless Steel: Contains molybdenum for enhanced corrosion resistance, ideal for marine and chemical environments.

321 Stainless Steel: Titanium is added to improve high-temperature resistance, making it suitable for high-temperature conditions.

Specifications

Outer Diameter: Typically ranges from 6mm to 1000mm, with customization available as needed.

Wall Thickness: Generally varies between 0.5mm and 30mm, selectable based on specific application requirements.

Length: Standard length is approximately 6 meters, with custom lengths available upon request.

Production process

Welding process: Stainless steel welded pipes are made by welding stainless steel strips or plates into tubes. The welding method can be arc welding, laser welding or high-frequency welding to ensure the strength and sealing of the weld.

Surface treatment

Surface finish: Different surface treatments such as polishing, pickling, brushing, etc. can be provided according to requirements to improve aesthetics and corrosion resistance.

Advantages

Corrosion resistance: Stainless steel material has excellent corrosion resistance and is suitable for use in harsh environments.

High Strength: The structure of the welded pipe makes it perform well when subjected to high pressure and temperature.

Economical: Compared with seamless pipes, welded pipes have lower production costs and are suitable for large-scale applications.

Application Areas

Chemical Industry: Used to transport chemicals and corrosive liquids.

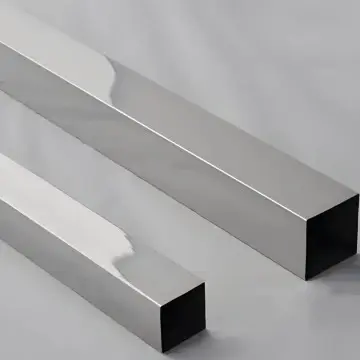

Construction industry: used for structural support and decoration.

Food and pharmaceutical industry: For use in pipe systems with high hygienic requirements.

Automotive Industry: Used in automotive parts and exhaust systems.

Maintenance

Regular Inspection: It is recommended to inspect the pipes regularly to ensure there are no leaks and corrosion.

Clean: Keep the pipe surface clean to avoid the accumulation of dirt and chemicals.

Product Specifications

| Product Name | Stainless steel pipe / tube |

| Type | Seamless or Welded |

| Material (DIN) | 1.4301 1.4306 1.4541 1.4401 1.4404 1.4571 1.4539 1.44621.4410 1.4833 1.4845 |

| Outter Diameter (OD) | 3-1220mm |

| Thickness | 0.4-120mm |

| Length | 6000mm 5800mm 12000mm or Customized |

| Surface Finished | No.1 No.3 No.4 HL 2B BA 4K 8K 1D 2D |

| End/Edge | Plain Mill |

| Technique | Cold Drawn or Hot |

| Standard | ASTM AISI DIN JIS GB EN |

| Certificate | ISO SGS CE BV |

| Application | Construction, Industry, decoration and foodstuff etc. |

Application

Capable of cutting carbon steel, stainless steel, copper, aluminum, and various other pipes and profiles, including tubes, pipes, oval pipes, rectangular pipes, H-beams, I-beams, angles, and channels. This equipment is extensively used in pipe profile processing, shipbuilding, structural frameworks, steel construction, marine engineering, oil pipelines, and other industries.

transport

010203040506070809