0102030405

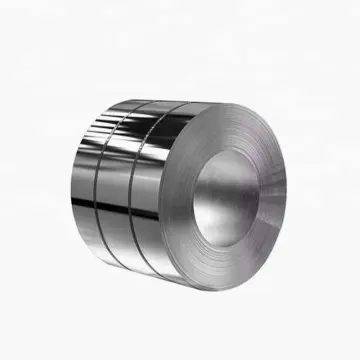

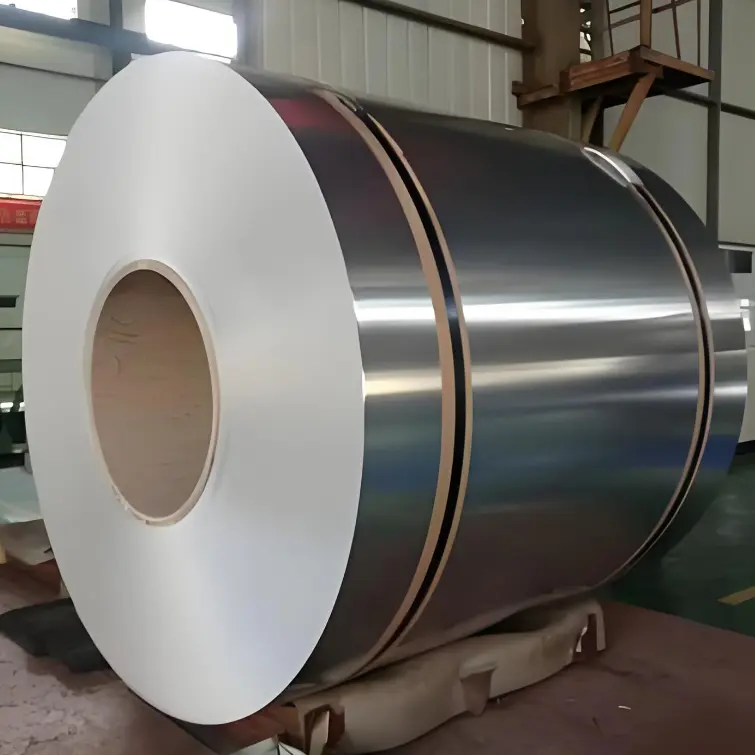

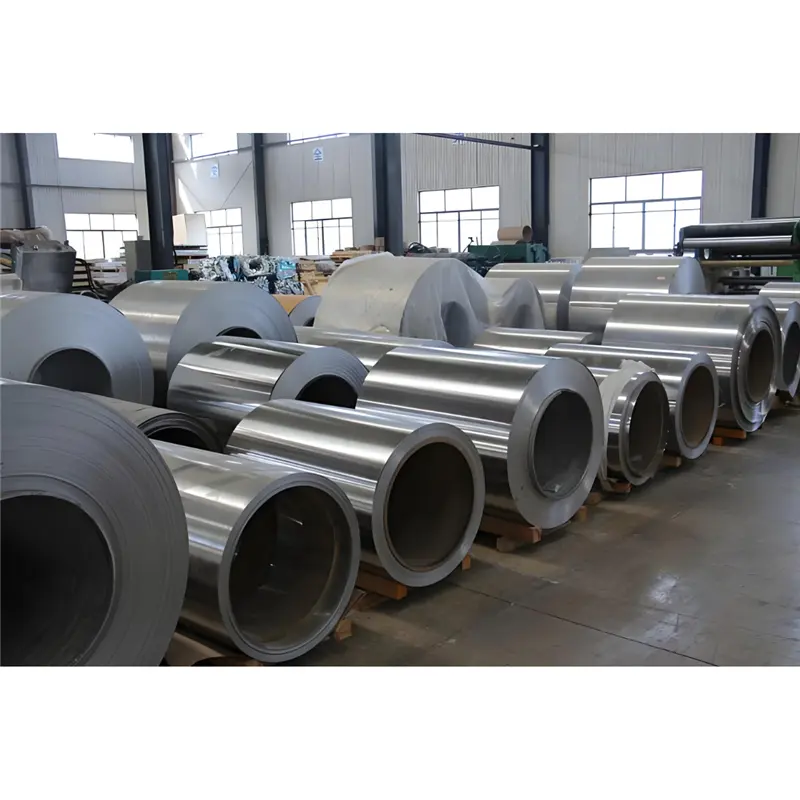

Aluminum Coil 7075/3005/2A12/5052

Product Description

Product Name Aluminum coil, Aluminum foil, Aluminum alloy coil, Aluminum alloy roll

Grade 1000, 2000, 3000, 4000, 5000, 6000series

a) 1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc.

b) 2000 Series: 2014, 2024, etc.

c) 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc.

d) 4000 Series: 4045, 4047, 4343, etc.

e) 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5454, 5754, 5A06, etc.

f) 6000 Series: 6061, 6063, 6082, 6A02, etc.

Materials

Aluminum alloy: Aluminum coils usually use different series of aluminum alloys, such as 1050, 1060, 1100, 3003, 5052, 6061, etc. The specific alloy type can be selected according to application requirements.

Specifications

Thickness: The thickness of aluminum coils is usually between 0.2mm and 6mm, and the specific thickness can be customized according to requirements.

Width: Common widths range from 100mm to 2000mm, which can be provided according to customer needs.

Length: Aluminum coils are usually provided in the form of coils, and the length can be customized according to customer needs.

Surface treatment

Surface Finish: The surface of the aluminum coil can be anodized, coated, polished, etc. to improve aesthetics and corrosion resistance.

Color Selection: A variety of color options are available to meet different decoration needs.

Advantages

Lightweight and high strength: Aluminum has low density and good strength, suitable for lightweight design.

Corrosion resistance: The naturally formed oxide layer of aluminum material provides good corrosion resistance.

Good processability: Aluminum coils are easy to cut, form and weld, suitable for various manufacturing processes.

Application Areas

Construction industry: used for roofs, walls, window frames, doors and other building materials.

Automotive industry: used in automobile body, chassis and interior parts.

Electronic Industry: Used in electrical housings, radiators, etc.

Packaging industry: used for food packaging, aluminum foil, etc.

Maintenance

Regular Inspection: It is recommended to regularly inspect the surface of the aluminum coil to ensure that it is free of oxidation and damage.

CLEAN: Keep the surface clean to avoid accumulation of dirt and chemicals.

Product size

Width 2mm-2200mm

Thickness 0.1mm-200mm

Length as required

Standard GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc

Temper

0-H112,T3-T8, T351-851

Surface

mill, bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc

Application

1)Further making utensil

2)Solar reflective film

3)The appearance of the building

4)Interior decorating; ceilings, walls,etc

5)Furniture cabinets

6)Elevator decoraction

7)Signs, nameplate,bags making

8)Decorated inside and outside the car

9)Household appliances: refrigerators, microwave ovens, audio equipment, etc

transport

010203040506070809