In the manufacturing industry, "Carbon Steel Plate" plays a crucial role. Experts highlight its versatility and strength. John Smith, a renowned materials engineer, states, “Carbon Steel Plate is fundamental in various applications due to its durability and cost-effectiveness.”

Manufacturers often choose carbon steel over other materials. Its ability to withstand heavy loads makes it ideal for construction. However, one must consider the environmental impact of carbon steel production.

Despite its benefits, there are challenges. Corrosion resistance can be an issue. Careful treatment is necessary to extend its lifespan. The balance between cost and quality is essential. Companies must continually evaluate their choices in materials.

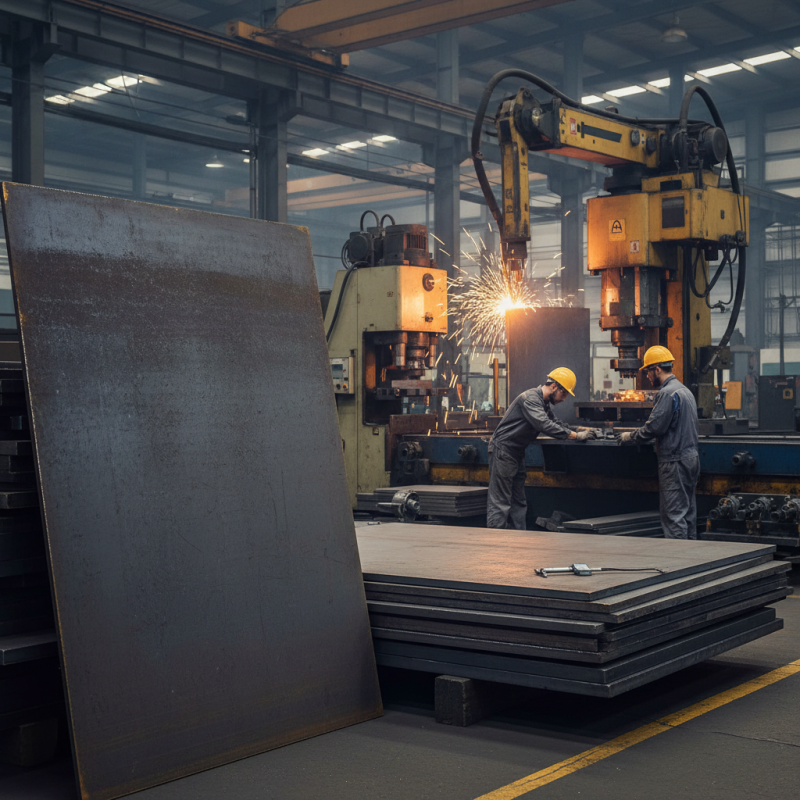

Carbon steel plates play a vital role in manufacturing industries. They are known for their versatility and strength. These plates are used in various applications, from construction to machinery. Their ability to withstand heavy loads makes them a preferred choice for many projects.

One significant benefit of carbon steel plates is their cost-effectiveness. They offer a suitable strength-to-weight ratio. This means manufacturers can reduce costs without sacrificing quality. Additionally, carbon steel plates are easier to source, simplifying supply chain logistics. Simple availability often translates to quicker project timelines.

Tips: Consider the thickness of the plate you need. Thicker plates provide more durability, but they may also increase weight. Additionally, evaluate the environment where the plates will be used. Exposure to moisture can affect the steel's longevity.

Another point to consider is the finishing process. Carbon steel plates may require treatments to prevent rust. This adds an extra layer of protection. Yet, the treatment process can lengthen the project timeline. It’s crucial to balance durability with time constraints. Keeping quality and efficiency in mind is essential for successful fabrication.

Carbon steel plates offer a remarkable high strength-to-weight ratio, making them essential in manufacturing. This characteristic allows manufacturers to reduce material usage while maintaining structural integrity. For instance, high-strength low-alloy (HSLA) carbon steel can achieve yield strengths of around 50,000 psi, while remaining relatively lightweight. In applications like automotive and aerospace, this benefit translates into fuel efficiency and enhanced performance.

Moreover, carbon steel plates can be tailored through various heat treatments. Adjusting the carbon content impacts strength and ductility. Some studies show that steels with lower carbon content can be manipulated to have better elongation properties. This versatility appeals to engineers and designers, yet it requires careful balancing. Overlooking the right alloying elements can lead to weaknesses.

Interestingly, while carbon steel plates excel in strength, they may present challenges in corrosive environments. Protective coatings often become necessary to enhance longevity. Some manufacturers opt for more expensive materials instead, citing the risks of corrosion in harsh conditions. This decision prompts reflection on the trade-offs between upfront costs and long-term performance. Balancing these factors is crucial for effective project outcomes.

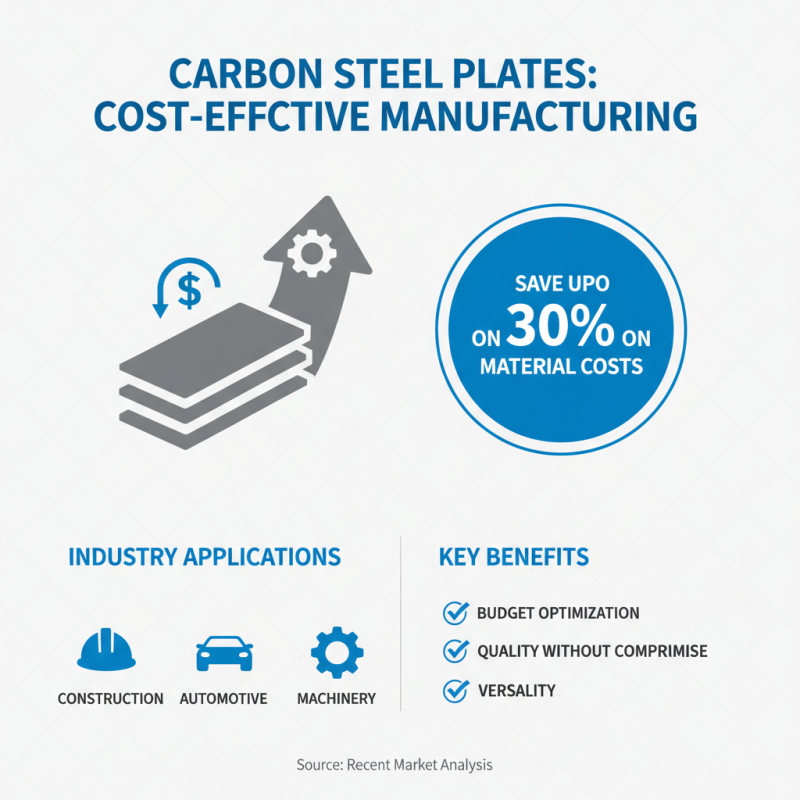

Carbon steel plates are often praised for their cost-effectiveness in various production processes. They are widely used in industries like construction, automotive, and machinery. A recent market analysis indicates that carbon steel can reduce material costs by up to 30% compared to more expensive alloys. This reduction makes it a popular choice for manufacturers looking to optimize their budgets without sacrificing quality.

However, the lower cost does come with some trade-offs. Carbon steel is prone to corrosion when exposed to moisture, which may raise long-term maintenance costs. According to industry reports, nearly 20% of maintenance budgets in companies using carbon steel are allocated to corrosion-related issues. Hence, while it is cheaper upfront, the potential for increased upkeep can be a significant hidden cost.

Moreover, manufacturers must consider the sustainability aspect. The production of carbon steel is energy-intensive, contributing to greenhouse gas emissions. A study by the International Energy Agency revealed that the steel sector accounts for about 7% of global CO2 emissions. Thus, while the material is economically attractive, its environmental impact should not be overlooked. Companies need to find a balance between cost savings and sustainability.

Carbon steel plates are gaining traction across diverse industries, primarily due to their exceptional versatility. In construction, they serve as fundamental components in buildings, bridges, and infrastructure. According to a recent report from the Steel Manufacturers Association, carbon steel accounts for approximately 70% of total steel production in the U.S. The adaptability of these plates supports various applications, from structural beams to reinforcements. Their strength-to-weight ratio often reduces material costs, yet some industries struggle with the variability in quality.

The manufacturing sector also benefits significantly from carbon steel plates. They are integral in automotive production, machine fabrication, and tool making. For instance, a report from the World Steel Association noted that carbon steel represents around 40% of the raw materials used in vehicle manufacturing. This presence highlights its importance, yet the reliance on recycled materials raises concerns about consistency and standardization. Manufacturers must often address these challenges to maintain quality in their end products. Ultimately, while carbon steel plates hold great promise, the need for stringent quality controls is critical in preventing failures in applications.

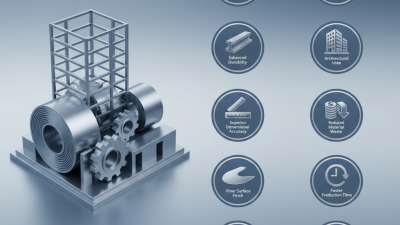

Carbon steel plates are known for their enhanced durability and longevity. When properly manufactured, these products can withstand significant stress and wear. They are often used in industries that require robust materials, such as construction and manufacturing. The toughness of carbon steel plates ensures they perform well under various conditions, whether in extreme temperatures or heavy load scenarios.

One notable aspect is their resistance to deformation. This makes them ideal for structural support. However, not all carbon steel is created equal. Factors such as the carbon content and heat treatment can influence their overall performance and lifespan. Some plates might corrode if not treated properly, which is a concern in humid environments. Regular maintenance is essential to ensure their longevity.

Additionally, the aesthetic of carbon steel often appeals to manufacturers. It can be finished in various ways to enhance appearance and functionality. Still, the industry sometimes overlooks these details. A lack of attention can lead to premature wear. It’s vital to weigh these aspects when choosing carbon steel plates for specific applications.

Carbon Steel Plate plays a crucial role in the manufacturing sector, offering numerous advantages that enhance production efficiency. One of the primary benefits is its high strength-to-weight ratio, allowing for the creation of robust products without adding unnecessary weight. Additionally, Carbon Steel Plate is known for its cost-effectiveness, making it an economically viable option for various production processes.

Versatile in application, Carbon Steel Plates are utilized across multiple industries, from construction to automotive, reflecting their adaptability. Furthermore, these plates offer enhanced durability and longevity, ensuring that products withstand wear and tear over time. Finally, the improved weldability and machinability of Carbon Steel Plates facilitate easier fabrication and assembly, making them a preferred choice for manufacturers aiming for high-quality outcomes in their projects.