In the realm of industrial applications, the significance of using high-quality materials cannot be overstated. Among these materials, the Stainless Steel Coil stands out due to its unmatched versatility and durability. Renowned industry expert Dr. John Smith, a leading metallurgist with over 20 years of experience, remarks, "The use of Stainless Steel Coils in various industrial settings not only enhances product efficiency but also significantly extends the lifespan of components." This statement encapsulates the essence of why many industries are now gravitating towards stainless steel coils as a preferred material.

The benefits of Stainless Steel Coils are multi-faceted, ranging from their resistance to corrosion and extreme temperatures to their recyclable nature, making them an eco-friendly choice. As industries continue to seek solutions that meet both performance and sustainability criteria, stainless steel coils serve as a reliable option that aligns with modern operational demands. In the following sections, we will explore the top 10 benefits of utilizing Stainless Steel Coils in industrial applications, shedding light on how they can optimize processes, reduce maintenance costs, and promote longevity in various applications.

Stainless steel coils are increasingly recognized in industrial applications for their exceptional corrosion resistance, making them a preferred choice in harsh environments. According to a report by the International Stainless Steel Forum, stainless steel grades with high chromium and nickel contents exhibit significant resistance to various corrosive agents, including acids and chlorides. This property is crucial for industries such as food processing, petrochemicals, and marine environments, where exposure to corrosive substances can compromise the integrity of materials. The durability of stainless steel coils translates to longer service life and reduced maintenance costs, reinforcing their value in industrial applications.

Tips: When selecting stainless steel coils for your specific application, consider the environmental factors involved. For instance, a higher nickel content often enhances corrosion resistance, particularly in chloride-rich environments. Additionally, ensure that the surface finish is appropriate for the intended application, as smoother finishes generally offer better resistance to corrosion due to reduced surface roughness.

Another benefit of stainless steel coils is their recyclability. Recent data from the World Steel Association indicates that approximately 85% of stainless steel can be recycled without compromising its properties. This eco-friendly aspect not only contributes to sustainable practices but also reduces material costs in the long run. Employing stainless steel coils can provide a competitive edge in both performance and environmental responsibility.

Stainless steel coils have gained significant traction in various industrial applications, primarily due to their enhanced durability and longevity. Unlike traditional materials, stainless steel is less prone to corrosion and degradation, which leads to a longer service life for industrial equipment. According to the International Stainless Steel Forum (ISSF), stainless steel can withstand harsh environments, including extreme temperatures and exposure to chemicals, making it an ideal choice for industries such as oil and gas, food processing, and pharmaceuticals. The material’s strength and resilience can reduce maintenance costs and downtime, as equipment is less likely to suffer from rust or other forms of deterioration over time.

Moreover, the lifecycle cost analysis presented by industry experts shows that while the initial investment in stainless steel coils may be higher than other materials, the long-term savings offset this. A report by the World Steel Association indicates that facilities utilizing stainless steel components experience a maintenance reduction of up to 30%. This substantial decrease in maintenance needs directly contributes to improved productivity levels, allowing companies to allocate resources more efficiently. By choosing stainless steel coils, industries can ensure their equipment remains reliable and operational for extended periods, bolstering overall productivity and financial performance.

Stainless steel coils play a crucial role in enhancing hygienic properties within the food and pharmaceutical industries, where cleanliness and sterility are paramount. The inherent characteristics of stainless steel, such as its non-porous surface and resistance to corrosion, make it an ideal material for applications requiring high sanitation standards. According to a report by the International Journal of Food Microbiology, stainless steel surfaces significantly reduce microbial contamination, providing a safer environment for food processing. A well-maintained stainless steel surface can achieve over 99% reduction in bacteria, which is critical for maintaining product integrity and the safety of consumers.

Moreover, the use of stainless steel coils helps in complying with stringent regulations set forth by health authorities. The Food and Drug Administration (FDA) emphasizes the importance of using materials that do not leach harmful substances into food or pharmaceuticals. Stainless steel meets these stringent criteria, as it does not react with food products, unlike some other metals. Additionally, the Global Hygiene Council reports that facilities using stainless steel components experience fewer contamination incidents, leading to lower operational costs and improved product quality. By investing in stainless steel coils, industries can enhance their overall hygienic practices, ensuring that their products are safe for consumption and compliant with health regulations.

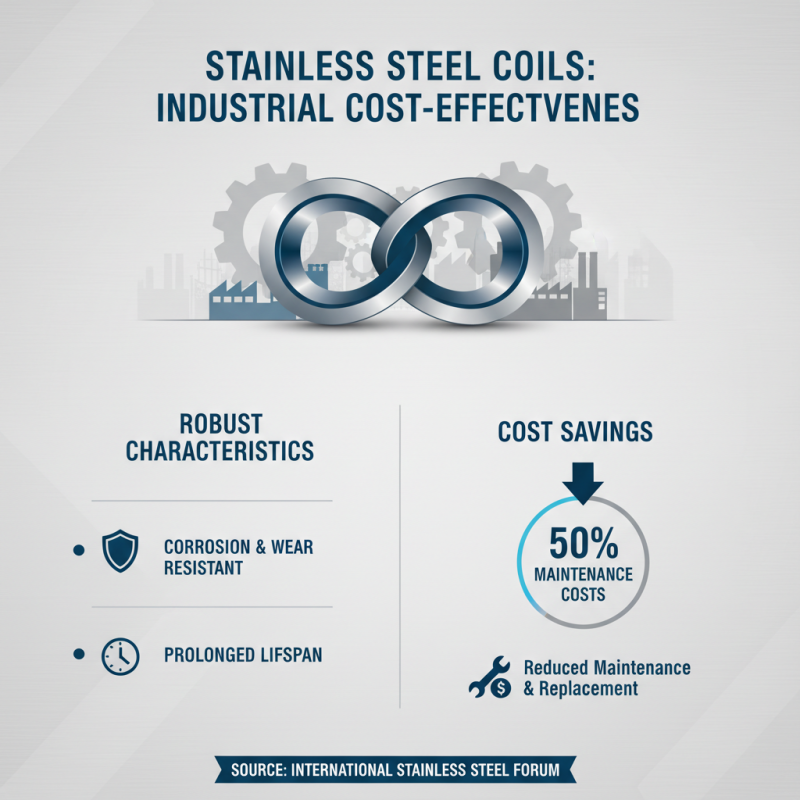

Stainless steel coils have become a staple in industrial applications due to their robust characteristics, notably in terms of cost-effectiveness linked to reduced maintenance and replacement needs. According to a report by the International Stainless Steel Forum, the use of stainless steel in various industries can lead to maintenance costs that are up to 50% lower compared to carbon steel alternatives. This is primarily because stainless steel’s resistance to corrosion and wear significantly prolongs the lifespan of machinery and components, thereby reducing the frequency and cost associated with replacements.

Moreover, an analysis by the Global Stainless Steel Market Research indicates that industries utilizing stainless steel coils experience not only lower upkeep costs but also enhanced operational efficiency. The durability of stainless steel allows for longer intervals between scheduled maintenance, leading to decreased downtime. For instance, manufacturing facilities have reported saving an average of 20% on maintenance budgets when switching to stainless steel from traditional materials. These economic advantages, combined with the material's sustainability benefits, underscore the growing preference for stainless steel coils across multiple sectors, driving innovation and efficiency in industrial practices.

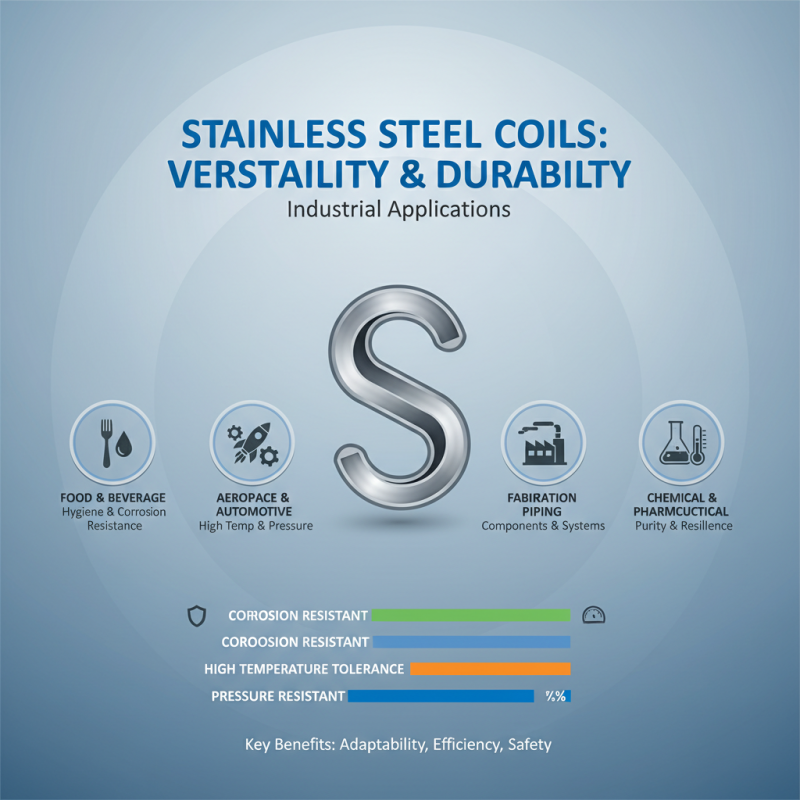

Stainless steel coils are increasingly favored across various industrial sectors due to their impressive versatility and durability. From the food and beverage industry to aerospace and automotive applications, these coils provide efficient solutions in environments that require resistance to corrosion, high temperatures, and pressure. Their adaptability allows manufacturers to utilize stainless steel in various processes, such as fabricating components, creating tanks, or producing piping systems that meet stringent hygiene and safety standards.

When considering stainless steel coils for your next project, it’s important to keep in mind a few tips to maximize their benefits. First, assess the specific requirements of your application, such as temperature ranges and exposure to corrosive substances, to choose the right grade of stainless steel. Second, ensure proper fabrication techniques are employed during installation to maintain the integrity and longevity of the material. Lastly, regular maintenance and cleaning can significantly enhance the lifespan of stainless steel components, making them an even more cost-effective choice for your business.

By leveraging the versatility of stainless steel coils, industries can streamline their operations and improve product quality. This material’s ability to meet diverse needs makes it a reliable option, whether you're in manufacturing, construction, or any other sector seeking durable and efficient solutions.