Galvanized pipes have long been a staple in plumbing projects, celebrated for their durability and resistance to corrosion. According to the Global Plumbing Report 2023, the demand for galvanized pipes is expected to grow by 5% annually through the next decade, driven by the construction and renovation sectors. This rising trend underscores the continued importance of galvanized pipe in both residential and commercial applications. Industry expert Dr. Emily Chen, a leading researcher in plumbing materials, emphasizes, "The reliability of galvanized pipes is unmatched, making them an excellent choice for various plumbing needs."

As the construction landscape evolves, the choice of materials remains critical for ensuring longevity and safety within plumbing systems. Galvanized pipes, characterized by their zinc-coated exterior, not only prevent rust but also contribute to lower overall maintenance costs, making them a preferred option for many contractors. The Plumbing Innovation Index also highlights that more than 60% of plumbing professionals cite galvanized pipes as their top recommendation for new installations. With such significant industry support, understanding the best galvanized pipe types can significantly enhance the success of your plumbing projects.

Galvanized pipes are a popular choice in plumbing projects due to their corrosion-resistant properties, which are achieved by coating steel or iron pipes with a layer of zinc. There are several types of galvanized pipes, each suited for different applications. The most common types include standard rigid galvanized pipes, which are typically used in construction and structural applications. Their sturdy design makes them ideal for carrying water, gas, and other substances safely and efficiently.

Another type is galvanized steel pipe, often employed for both residential and commercial water supply systems. Its strength and durability allow it to withstand high pressures, making it a reliable option for plumbing systems. Additionally, there are also galvanized pipe fittings that complement these pipes, providing essential connections and transitions in plumbing layouts. These fittings come in various shapes and sizes, ensuring that they can accommodate diverse installation requirements while maintaining the integrity and functionality of the plumbing system.

Galvanized pipes have long been a popular choice in plumbing applications due to their unique advantages. One of the key benefits of using galvanized pipe is its resistance to corrosion. According to a report by the National Association of Home Builders, galvanized steel can last over 50 years, making it a durable option for both residential and commercial plumbing systems. The zinc coating provides a protective layer that minimizes the impact of moisture and prevents rust, leading to improved overall longevity and performance.

Additionally, galvanized pipes exhibit strong resistance to physical damage and wear. This makes them suitable for high-pressure systems and general plumbing needs where durability is critical. A study conducted by the American Water Works Association indicates that galvanized pipes maintain their structural integrity even under heavy loads and extreme temperatures. Furthermore, the lower maintenance costs associated with less frequent replacements can lead to significant savings over time, reinforcing their practicality for various plumbing projects. As homeowners and builders look for reliable long-term solutions, the advantages offered by galvanized pipes remain hard to overlook.

When selecting galvanized pipe types for plumbing projects, it's crucial to consider several factors to ensure optimal performance and longevity. First and foremost, the intended application of the pipes should dictate the selection process. For instance, pipes intended for residential plumbing may differ from those used in industrial settings. Evaluating the water pressure and temperature in your plumbing system can guide you in choosing the appropriate thickness and diameter of the galvanized pipes, ensuring they can withstand the required conditions.

Additionally, it’s essential to examine the corrosion resistance of various galvanized pipe options. Galvanization involves coating the steel pipe with zinc, which protects it against rust. However, the effectiveness of this coating can vary between manufacturers and pipe types. Therefore, opting for pipes with a higher zinc coating thickness may offer better protection over time. Lastly, local building codes and regulations must not be overlooked; ensuring compliance can help avoid costly future modifications and maintain safety standards in your plumbing systems.

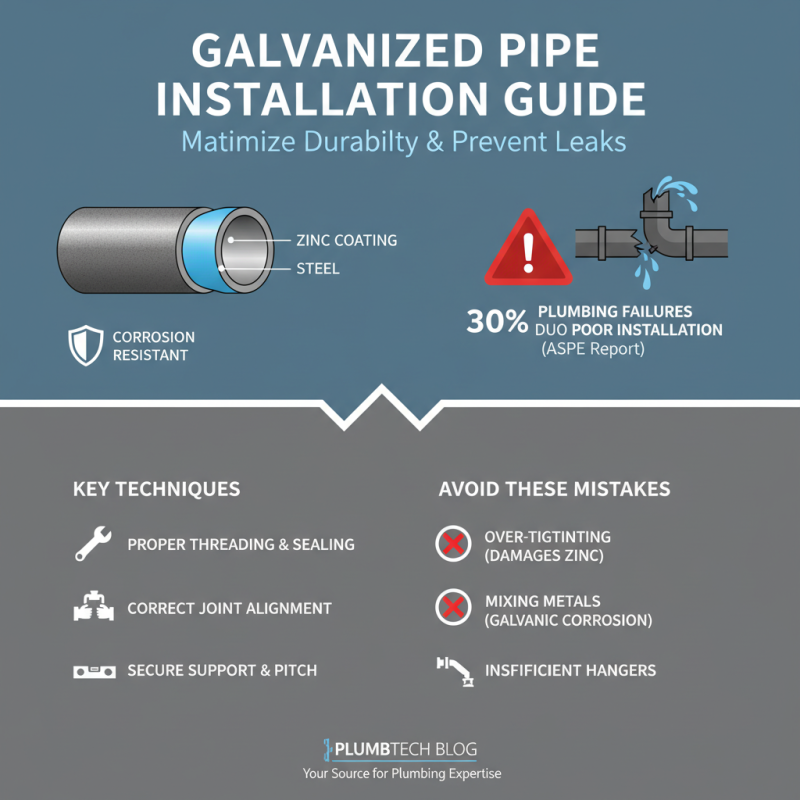

When it comes to installing galvanized pipes in plumbing projects, understanding the appropriate techniques is crucial for ensuring durability and functionality. Galvanized pipes, known for their steel composition coated with zinc, offer excellent resistance to corrosion compared to other piping materials. However, proper installation is vital to maximize their lifespan, as incorrect techniques can lead to leaks and premature wear. According to a recent industry report by the American Society of Plumbing Engineers, nearly 30% of plumbing failures are attributed to inadequate installation practices.

To ensure a successful installation, begin by accurately measuring and cutting the pipes to the required lengths. Use a pipe cutter rather than a hacksaw to avoid burrs that can impede flow and create potential weak points. When joining pipes, ensure that you utilize proper threading techniques or use appropriate fittings to maintain a tight seal. It's also advisable to apply pipe joint compound to threaded connections to enhance sealing and prevent leaks.

Tips: Always test your plumbing system for leaks after installation by pressurizing the pipes with water. Additionally, consider using pipe insulation to protect against extreme temperatures, which can cause expansion and contraction, leading to potential joint separation. Investing attention into these installation practices can significantly extend the life of your plumbing system, leading to cost savings in repairs and maintenance in the long run.

When dealing with galvanized pipe systems, regular maintenance is crucial to ensure longevity and optimal performance. One of the primary concerns with galvanized pipes is the accumulation of rust and mineral deposits over time, which can reduce water flow and lead to leaks. Therefore, it is vital to conduct periodic inspections to identify any potential issues early on.

Tips for Maintenance: Check for leaks or signs of corrosion at least twice a year. If you notice discolored water or a drop in water pressure, it may indicate buildup within the pipes. Flushing the system periodically can help remove rust and debris, promoting better water flow. Additionally, consider using a water softener if you live in an area with hard water, as this can reduce mineral buildup within the pipes.

Another key aspect of maintenance is ensuring that the pipes are properly insulated, especially in colder climates. Insulation helps prevent freezing and bursting during the winter months, which are common problems in galvanized systems. Tips for Maintenance: Use pipe insulation sleeves or wrap to cover exposed sections of the piping, particularly in unheated areas, such as basements and crawl spaces. This simple step can save you from costly repairs and extend the life of your galvanized pipes.