Seamless Pipe is a remarkable engineering product. Its unique construction allows for strength and durability in various applications. Industries rely on seamless pipes for transporting fluids under high pressure. They are commonly used in oil and gas, power generation, and construction sectors.

One key advantage is their resistance to leaks. This makes seamless pipes a preferred choice for critical operations. However, not all applications may suit seamless pipe use. Some projects could benefit from welded pipes instead. It's essential to assess the specific needs beforehand.

Moreover, seamless pipes can be costly. Their production process is complex and requires precision. This can limit their use in smaller projects. Understanding the nuances of each application is crucial. In the end, the choice of seamless pipe should match the project requirements.

Seamless pipes are pivotal in various industries. They are crucial in oil and gas, construction, and automotive sectors. According to recent reports, the global seamless pipe market is projected to reach $30 billion by 2027. This reflects a growing demand.

In the oil and gas sector, seamless pipes transport fluids under high pressure. They are resistant to corrosion, making them ideal for harsh environments. Data indicates that around 70% of the seamless pipe demand arises from this industry. In construction, these pipes provide strength and durability for structural applications. They are often used for pipelines, frameworks, and even architectural support.

The automotive industry utilizes seamless pipes in manufacturing light-weight vehicles. This promotes fuel efficiency, which is essential with rising environmental concerns. However, the seamless pipe market faces challenges. Production costs can be high, and the availability of skilled labor is limited. These factors require ongoing attention to ensure industry growth.

| Application | Industry | Material Type | Diameter Range (inches) | Temperature Resistance (°F) |

|---|---|---|---|---|

| Oil & Gas Transport | Oil and Gas | Carbon Steel | 2 - 36 | -20 to 300 |

| Construction | Manufacturing | Alloy Steel | 1 - 20 | -40 to 250 |

| Chemical Processing | Chemical | Stainless Steel | 1 - 18 | -30 to 500 |

| Power Generation | Energy | Carbon Steel | 2 - 30 | -20 to 750 |

| Automotive | Automobile | Alloy Steel | 1 - 12 | -20 to 250 |

| Aerospace | Aviation | Titanium | 0.5 - 6 | -60 to 600 |

| Marine Applications | Marine | Stainless Steel | 1 - 15 | -20 to 300 |

| HVAC Systems | HVAC | Carbon Steel | 2 - 10 | -20 to 250 |

| Pipelines | Infrastructure | Carbon Steel | 6 - 48 | -30 to 400 |

| Medical Equipment | Healthcare | Stainless Steel | 0.5 - 5 | -40 to 250 |

Seamless pipes are crucial in various industries due to their unique characteristics. They are made without seams or welds, which minimizes potential weaknesses. This feature makes them incredibly strong, perfect for high-pressure applications. Seamless pipes can endure extreme temperatures, whether too hot or too cold. This thermal resistance is essential in oil and gas sectors, as well as in chemical processing plants.

Another key characteristic is their uniformity. Seamless pipes provide consistent wall thickness, leading to better performance under pressure. This uniformity helps in reducing leaks and failures. Additionally, they exhibit excellent corrosion resistance. The smooth interior allows for efficient flow, which is favored in hydraulics. However, the production of seamless pipes can be costly, and the manufacturing process can lead to defects. These vulnerabilities must be addressed to ensure reliability in critical applications. Proper quality control is essential to prevent potential issues.

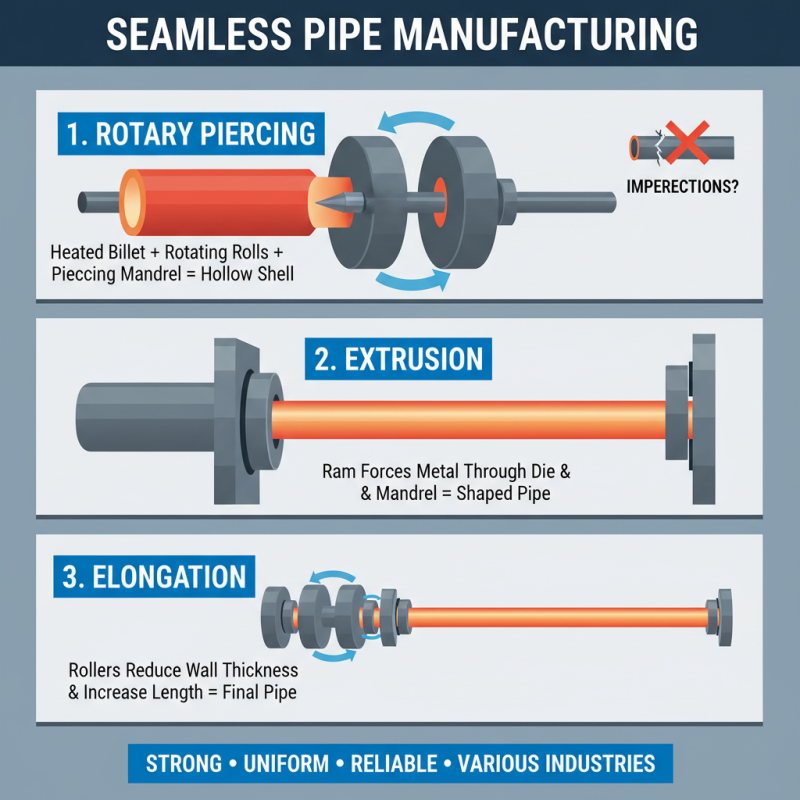

Seamless pipes are integral in various industries. Their manufacturing process is crucial and often complex. The main methods include rotary piercing, extrusion, and elongation. In rotary piercing, a heated metal billet is rotated and pierced. This creates a hollow tube. It’s efficient but can lead to challenges, such as imperfections.

Extrusion is another popular method. Here, metal is forced through a die at high temperatures. This process forms a seamless pipe directly. While efficient, it can result in surface defects. Careful monitoring during this stage is vital. Issues often arise if the temperature or pressure isn’t controlled properly.

After these processes, elongation may occur. This method stretches the pipe to desired dimensions. However, it can weaken the structure if done excessively. Engineers must balance dimensions and material strength. Additionally, factors like temperature need constant adjustment. Overall, these processes require precision and can be riddled with challenges.

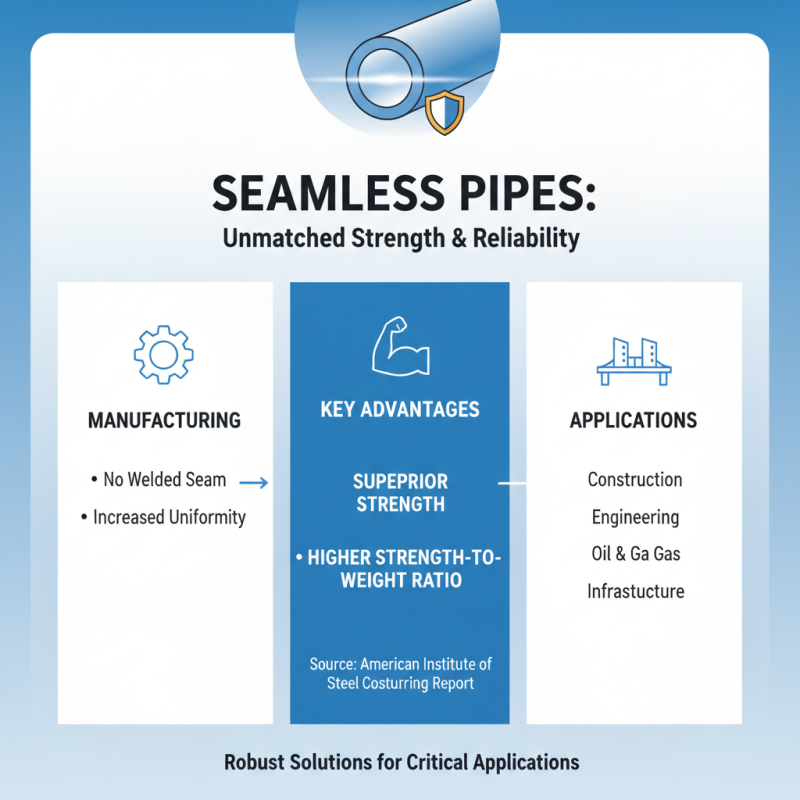

Seamless pipes have gained popularity in various industries due to their unique advantages. They are manufactured without welded seams, which makes them stronger and more reliable. According to a report from the American Institute of Steel Construction, seamless pipes offer a higher strength-to-weight ratio. This property allows for efficient and robust applications in construction and engineering.

Another important benefit of seamless pipes is their ability to withstand high pressures. The lack of welds means there are fewer weak points, making them ideal for applications in the oil and gas industry. A study by the International Journal of Engineering Research highlighted that seamless pipes can handle pressures over 20% higher than welded pipes. This characteristic is crucial for ensuring operational safety in high-stakes environments.

Despite their advantages, seamless pipes can be more expensive than welded options. The manufacturing process is complex and requires more raw materials. Additionally, not all applications require the enhanced properties of seamless pipes. An analysis by the World Steel Association indicates that welded pipes still dominate many sectors due to cost-effectiveness. Balancing the performance needs with budget constraints is essential for industries when choosing between these two types of pipes.

Seamless pipes have become essential in modern engineering. Their unique structure offers superior strength and durability. They are widely used in various industries, including oil and gas, construction, and manufacturing.

In the oil and gas sector, seamless pipes transport high-pressure fluids. These pipes minimize leakage risks, ensuring safety and efficiency.

In construction, seamless pipes play a vital role in structural applications. They support frameworks and can withstand heavy loads. Engineers prefer these pipes for their reliability. However, not all seamless pipes are created equal. Quality control remains a challenge. Flaws can occur during production, leading to potential failures.

The aerospace industry also utilizes seamless pipes in fuel systems. Their lightweight nature reduces overall weight, which increases fuel efficiency in aircraft. Yet, maintaining stringent safety standards is critical. The consequences of failure in aerospace can be severe. Each application carries its own set of challenges, requiring continuous innovation and improvement.