Carbon Pipe plays a vital role in various industries, yet many overlook its importance. According to John Smith, a leading expert in piping technologies, "Carbon Pipe is the backbone of structural integrity." His insight sheds light on why understanding this material matters.

These pipes are commonly used in oil and gas, water transportation, and construction. Carbon Pipe offers strength and durability. However, not all carbon pipes are created equal. Quality control is crucial. A small flaw can lead to significant issues down the line. Ensuring high standards in production is essential but often challenging.

Many industries face obstacles in implementation. The cost of high-quality Carbon Pipe can deter buyers. Additionally, outdated practices can hinder progress. Adopting new technologies and techniques is necessary for maximizing performance. Without proper investment, companies risk safety and efficiency. Carbon Pipe deserves attention, as neglecting its role may lead to future complications.

Carbon pipe, often used in industrial applications, plays a crucial role in various systems. Its primary composition includes carbon steel, which offers strength and durability. This material is favored for its ability to withstand high pressures and temperatures, making it suitable for transporting fluids and gases. However, not all carbon pipes are created equal. Variations in carbon content can affect performance, and understanding these differences is vital.

While the advantages of carbon pipe are clear, potential drawbacks exist. For instance, lower quality pipes may suffer from corrosion. This issue can lead to leaks, posing safety risks. Additionally, some carbon pipes may not meet required standards, resulting in unpredictable performance. Therefore, choosing the right carbon pipe requires careful consideration of its composition and intended use.

Carbon pipes are essential in construction, oil, and gas industries. Their versatility is remarkable, yet they require regular inspections. Neglecting maintenance can lead to severe problems down the line. Industry professionals must prioritize quality and ensure proper handling to enhance durability. These factors contribute to the overall effectiveness of carbon pipe systems.

The chart illustrates the typical composition of carbon pipes, highlighting the percentage of key elements like carbon, manganese, silicon, phosphorus, and sulfur. Understanding this composition is crucial for evaluating the mechanical properties and suitability of carbon pipes in various applications.

Carbon pipes are crucial components in various industries, including oil and gas, construction, and manufacturing. They come in several types, each serving specific needs. The most common types include welded pipes, seamless pipes, and carbon steel pipes. According to industry reports, the demand for carbon pipes is projected to grow by 5% annually, reflecting their significance.

Welded pipes are constructed by joining steel sheets. They are suitable for low-pressure applications. Seamless pipes, on the other hand, are made from a solid round steel billet that is heated and molded into shape. This provides higher strength and reliability. Carbon steel pipes find use in high-temperature applications due to their durability. Recognizing the variety in carbon pipe types is essential for selecting the right materials.

Tips: Always consider the application when choosing a pipe type. Evaluate pressure and temperature requirements carefully. Also, regularly inspect the pipes for wear or damage to ensure safety and efficiency. The right choice can save time and costs over the long term. Maintaining quality is key—flawed installations lead to bigger issues.

Carbon pipes are essential in many industries. Their strength and durability make them ideal for handling fluids and gases. In the oil and gas sector, carbon pipes are widely used for transporting crude oil and natural gas. Their resistance to corrosion enhances safety in harsh environments.

In construction, carbon pipes serve as effective conduits for water and waste. They are lightweight yet sturdy, which simplifies installation. For manufacturing, carbon pipes play a crucial role in various processes. They handle high-pressure applications efficiently, making them indispensable.

Tip: Always check the compatibility of carbon pipes with the substances being transported. Testing is key to avoiding failures.

In the automotive industry, carbon pipes contribute to improved efficiency. They help reduce weight without sacrificing strength. However, improper maintenance can lead to leaks over time. Attention to detail matters here.

Tip: Regular inspections are vital. Keep an eye out for any signs of wear or damage. Addressing issues early can save resources down the line.

Overall, carbon pipes have diverse applications. Their versatility is evident across many fields, but they require responsible management. The balance between functionality and maintenance is crucial.

| Industry | Application | Advantages of Carbon Pipes |

|---|---|---|

| Oil and Gas | Transport of hydrocarbons | High strength, resistance to corrosion |

| Construction | Structural support systems | Lightweight yet durable, cost-effective |

| Automotive | Exhaust systems | Excellent heat resistance, reduced weight |

| Manufacturing | Piping for fluid transport | High tensile strength, longevity |

| Aerospace | Fuel systems | Lightweight design, high performance |

| Utilities | Water distribution | Corrosion resistance, high pressure tolerance |

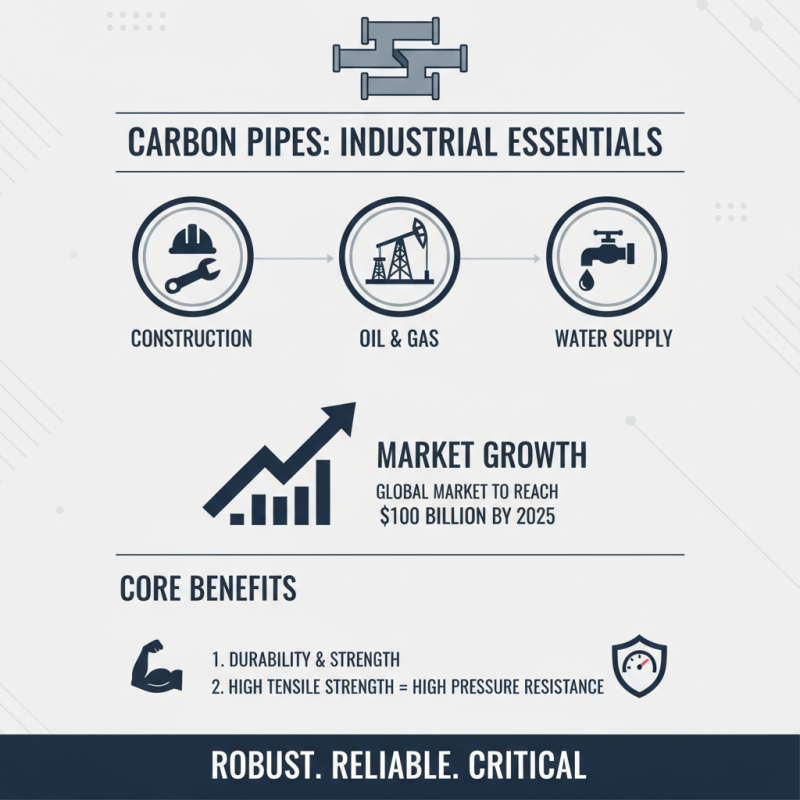

Carbon pipes are widely used in various industries due to their durability and strength. These pipes are essential in construction, oil and gas, and water supply systems. According to a recent industry report, the global carbon steel pipe market is projected to reach $100 billion by 2025, indicating robust growth. The high tensile strength of carbon pipes allows them to withstand high pressures without compromising safety.

One major benefit of using carbon pipes is their cost-effectiveness. These materials are usually cheaper than alternatives like stainless steel. They offer an excellent balance between price and performance. In addition, carbon pipes have a long service life, often exceeding 50 years with proper maintenance. This longevity can lead to lower replacement costs over time. However, considering their susceptibility to corrosion, proper coatings are necessary.

Thermal conductivity is another advantage. Carbon pipes can transfer heat efficiently, making them suitable for various applications. Studies have shown that well-insulated carbon pipes improve energy efficiency by reducing heat loss. However, installation requires skilled labor to ensure proper alignment and support. If not installed correctly, the pipes may fail, leading to costly repairs. Finding that balance between cost and maintenance is crucial for any project involving carbon pipes.

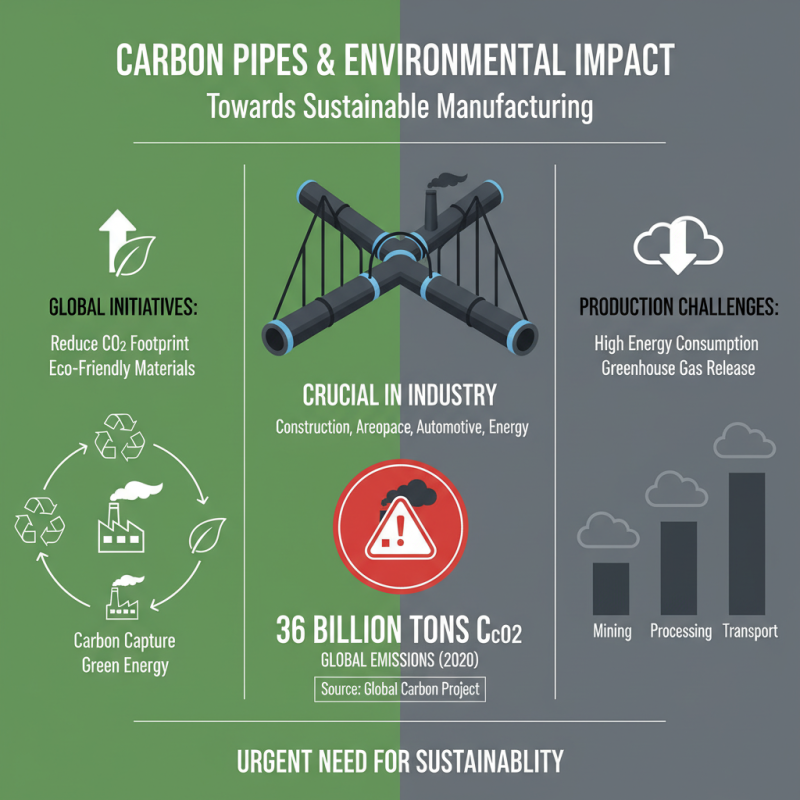

Carbon pipes are crucial in various industries, but their environmental impact raises concerns. The production process often involves significant carbon emissions. A report by the Global Carbon Project states that global carbon dioxide emissions reached approximately 36 billion tons in 2020. This figure highlights the urgent need for sustainable practices in manufacturing.

In terms of waste, carbon pipes can be problematic. Many end up in landfills after use. According to a survey by the World Economic Forum, around 300 million tons of plastic waste is generated each year. Though carbon pipes aren’t plastic, they share similar disposal challenges. Recycling options for carbon materials are limited. This raises questions about the lifecycle management of carbon pipes and the industry's commitment to sustainability.

Moreover, the energy consumption tied to carbon pipe production is significant. The International Energy Agency noted that the energy used in steel manufacturing contributes to about 8% of the world’s greenhouse gas emissions. This statistic prompts a necessary reflection on how the industry can innovate towards greener solutions. New techniques and materials are being explored, but progress is slow. The awareness of these impacts is growing, yet tangible actions lag behind.