In the world of electrical projects, the selection of materials plays a crucial role in ensuring efficiency, safety, and longevity. Among these materials, the copper strip stands out due to its excellent conductivity and versatility. Choosing the right copper strip is essential for achieving optimal performance in various applications, whether it be in electronics, power distribution, or specialized industrial uses.

When considering copper strips, one must evaluate several factors, including thickness, width, and resistance to corrosion. Each of these elements can significantly influence the effectiveness of your electrical systems. Furthermore, understanding the specific requirements of your project—such as load capacities and environmental conditions—will guide you in selecting the most suitable copper strip. By making informed decisions, you can enhance the reliability of your electrical projects while also maximizing their cost-efficiency.

In this guide, we will explore the critical aspects of choosing the right copper strip for your electrical needs. From material specifications to practical considerations, we aim to equip you with the knowledge necessary to make a sound choice that meets the demands of your project while maintaining high standards of quality and safety.

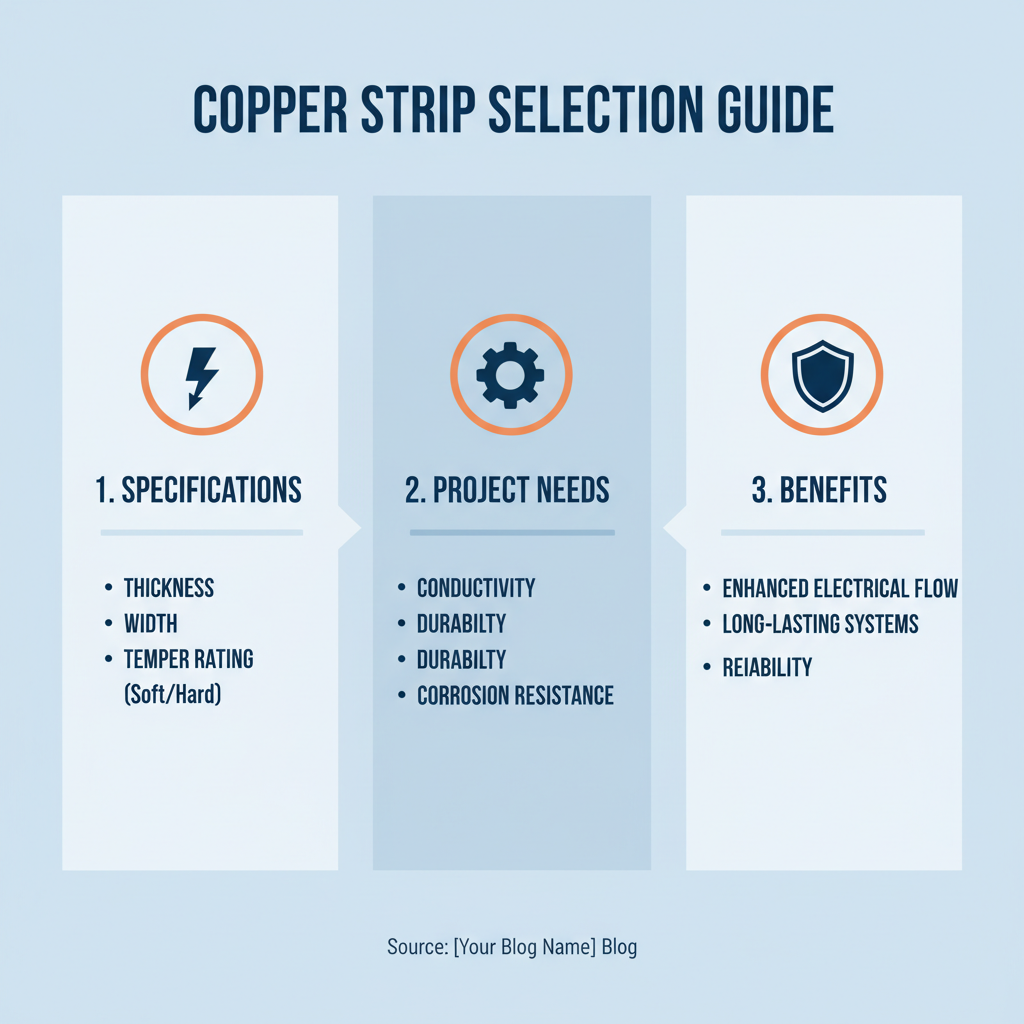

When selecting the right copper strip for electrical projects, it’s crucial to understand the specifications that meet your project needs. Copper strips come in various thicknesses, widths, and temper ratings that determine their versatility and application in different electrical setups. A well-chosen copper strip can enhance conductivity, ensure durability, and provide resistance to corrosion, which is essential in maintaining the integrity of electrical systems.

As the market for copper strips continues to grow, driven by rapid industrial advancements, it's essential to consider the quality of suppliers. The 2017 Top Ten High-Quality Suppliers of National Copper Strip Processing Enterprises are known for their commitment to high standards in manufacturing. By focusing on their specifications and reliability, you can make informed choices that align with the specific requirements of your projects, ensuring both safety and efficiency in electrical applications.

When selecting copper strips for your electrical projects, determining the appropriate thickness and width is crucial for ensuring optimal performance and safety. The thickness of copper strips is typically measured in mils or millimeters, and it directly impacts the strip's conductivity and current-carrying capacity. Thicker strips are more suitable for applications requiring higher current loads, as they can handle increased thermal and electrical stresses without overheating. For standard applications, a thickness of around 0.5 mm to 1 mm is often adequate, but for specialized needs, thicker strips may be necessary.

Width is another important consideration. The width of the copper strip should match the requirements of your specific project and the space constraints of your electrical setup. Wider strips can distribute electrical load more evenly, reducing the chances of hot spots that can lead to failures or hazards. When calculating the proper width, consider both the electrical demand and the physical layout of your components to avoid limitations in current flow. Balancing these dimensions will enhance the efficiency and reliability of the electrical connection in your project.

| Strip Thickness (mm) | Strip Width (mm) | Current Capacity (A) | Application |

|---|---|---|---|

| 0.5 | 10 | 10 | Low Power Circuits |

| 1.0 | 20 | 20 | Small Motors |

| 1.5 | 30 | 30 | Lighting Applications |

| 2.0 | 50 | 50 | HVAC Systems |

| 3.0 | 100 | 100 | Industrial Equipment |

When selecting a copper strip for electrical projects, two key factors to consider are electrical conductivity and temperature ratings. Copper is renowned for its excellent conductivity, making it an ideal choice for a wide range of electrical applications. The purity of the copper strip significantly affects its conductivity; higher purity means lower resistance, which leads to greater efficiency and performance in electrical circuits. It is crucial to choose copper strips that meet the specific conductivity requirements of your project, ensuring optimal energy transfer and minimal power losses.

Another vital aspect to evaluate is the temperature rating of the copper strip. Different electrical applications expose materials to varying temperature ranges, and choosing a strip with an appropriate temperature rating is essential for safety and durability. High-temperature environments may cause degradation in conducting materials, leading to increased resistance, potential failures, or safety hazards. Therefore, it is important to consult product specifications and select copper strips designed to withstand the thermal demands of your particular project. This careful evaluation of both conductivity and temperature ratings will ensure the reliability and effectiveness of your electrical systems.

When selecting the right copper strip for your electrical projects, it's essential to consider both quality and cost. Copper strips vary significantly in their purity, thickness, and manufacturing processes, all of which can impact their performance in electrical applications. Higher purity copper typically delivers better conductivity, but it may come with a higher price tag. Therefore, understanding your project's specific requirements can help in making a cost-effective decision.

Tips for selecting copper strips: First, assess the electrical load your project will handle. This evaluation will guide you in choosing the appropriate gauge and length of the copper strip. Second, compare prices from different suppliers, keeping an eye out for discounts on bulk purchases. Lastly, review product certifications to ensure the copper strips meet industry standards, which can prevent future issues related to performance and safety.

Ultimately, weighing the quality against the cost will empower you to choose the most suitable copper strip for your needs, ensuring both reliability and budget adherence in your electrical projects.

When it comes to sourcing and purchasing copper strips for electrical projects, understanding the right suppliers and quality standards is crucial. Begin by identifying reputable suppliers who specialize in copper products. Look for companies with positive customer reviews and a track record of reliability. Verify their certifications and the sourcing of their materials to ensure compliance with industry standards.

**Tips for Sourcing Copper Strips:**

- Always request samples before making a bulk purchase. This allows you to assess the quality and suitability of the copper strips for your specific project needs.

- Compare pricing from multiple suppliers, but don't compromise on quality for a lower cost. Sometimes, a higher initial investment can lead to better long-term performance.

Additionally, consider the specifications required for your project. Factors such as thickness, conductivity, and finish can significantly affect the performance of the copper strips. Communicate your project requirements clearly to suppliers and don’t hesitate to ask for expert advice if you’re unsure about the specifications.