When it comes to construction materials, the choice of metal can significantly impact a project's longevity and efficiency. Galvanized Plate offers unique benefits that set it apart. According to the American Galvanizers Association, galvanized steel structures can last over 50 years with minimal maintenance. This durability stems from a protective zinc coating that prevents rust and corrosion, making it ideal for harsh environments.

Additionally, the global demand for galvanized products has risen dramatically. A recent report from Market Research Future projected that the galvanized steel market will reach USD 175 billion by 2025. This trend is due to its versatility and resilience, appealing to a wide range of industries. However, some still question whether galvanized plate is always the best choice. The initial cost may deter some contractors, even though the long-term benefits often outweigh this concern.

Choosing Galvanized Plate might also prompt reflection on environmental impacts. Though it is a reliable option, the production processes can generate byproducts. Understanding these factors is essential for making informed decisions. As we look towards the future of construction materials, Galvanized Plate remains a compelling option worth consideration.

When considering construction materials, galvanized plates stand out for their unique advantages. These plates are coated with zinc to prevent rust. This protective layer makes them ideal for outdoor use. They can withstand harsh weather without deteriorating quickly. Builders often use them in roofing, siding, and structural components.

The durability of galvanized plates adds to their appeal. They require minimal maintenance, allowing projects to run smoothly. Over time, they can even save on replacement costs. However, there is a trade-off; some people notice difficulties with welding these plates. This can lead to wasted materials if not executed properly. Additionally, while galvanized plates resist corrosion well, they are not completely immune.

Overall, using galvanized plates in construction brings multiple benefits. They enhance longevity and structural integrity. Still, quality control during installation is essential. Misalignment can lead to frustration. Evaluating the specific requirements of your project is crucial. Each project's needs might highlight different strengths and weaknesses of this material.

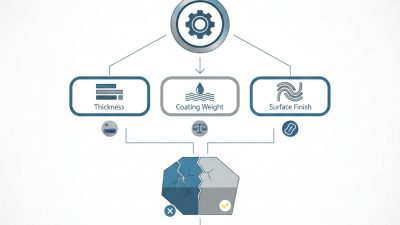

Galvanization is a vital process. It protects metal surfaces from rusting. This method involves coating steel with zinc. The primary goal is to enhance durability. When exposed to moisture, zinc reacts with elements. This forms a protective barrier against corrosion.

The galvanization process includes several steps. First, cleaning the metal removes contaminants. Next, the metal is dipped in molten zinc. This creates a thick, strong coating. The coated metal cools and solidifies. Finally, a layer of zinc oxide forms on the surface. This offers additional protection.

It's not flawless, though. Sometimes, uneven coatings occur. This can lead to weak spots. These flaws might compromise the metal's strength. It's essential to monitor the galvanization process closely. Regular inspections can help identify issues. Making adjustments ensures a quality finish. The balance of cost and quality is worth considering. Challenges can arise, but proper management will yield better results.

| Property | Benefits | Applications |

|---|---|---|

| Corrosion Resistance | Increased lifespan of the material | Construction, outdoor furniture |

| Durability | Withstands harsh environments | Industrial applications, bridges |

| Cost-Effectiveness | Lower maintenance costs | Pipelines, roofing materials |

| Aesthetic Appeal | Smooth and attractive surface finish | Decorative structures, signage |

| Eco-Friendly | Recyclable and reduces waste | Sustainable construction practices |

When considering materials for your next project, galvanized plates are an excellent choice. Their ability to resist corrosion sets them apart. This resistance stems from a protective zinc coating. Over time, this layer prevents rust and deterioration. Projects that require durability often benefit from using galvanized plates.

In construction or outdoor applications, galvanized plates provide long-lasting performance. They hold up against harsh weather and environmental challenges. This means lower maintenance costs over time. However, not all galvanized plates are the same. Some may not have sufficient coatings. Choosing the right thickness is crucial for optimal durability.

Tips: Always assess your project's specific needs. Look for galvanized plates with a high zinc content. This ensures better corrosion resistance. Regular inspections can help identify signs of wear. Stay proactive to maintain the integrity of your structures. Remember, even with galvanized plates, unexpected issues can arise. So, be prepared to evaluate and address any concerns that may emerge over time.

Galvanized plates are increasingly used across various industries. Their resistance to corrosion makes them ideal in many applications. For instance, in the construction industry, they provide structural integrity in bridges and buildings. According to a recent report by the American Galvanizers Association, galvanized steel's lifespan can exceed 50 years in certain environments. This durability reduces maintenance costs.

In the automotive sector, galvanized plates are crucial for vehicle body construction. They protect against rust and extend the life of cars significantly. A study indicated that 70% of vehicles now incorporate galvanized materials, improving safety and longevity. However, the challenge arises in balancing cost with the sustainability of these materials. Production can be resource-intensive, and methods can vary widely.

In manufacturing, galvanized plates serve as vital components in machinery. From conveyors to frameworks, their versatility shines through. Still, industries often face the issue of quality inconsistency. Not all galvanized plates provide the same level of protection, which can lead to unexpected failures. This calls for better standards and evaluations to ensure reliability.

Galvanized plate is a popular choice in construction projects for good reasons. Its cost-effectiveness is one of the key benefits. Galvanization protects metal from rust and corrosion. This durability means lower maintenance costs. You won't need to replace materials as often. Over time, these savings add up. This makes galvanized plates an economical option.

Sustainability is another important factor. Galvanized materials can be recycled. This reduces environmental impact. Using less raw material contributes to a greener planet. However, not all galvanized plates are the same. Some may have chemical coatings that could cause issues. It's vital to research where and how the material was produced.

Incorporating galvanized plates into your project can be beneficial. Yet, understanding the balance between cost and environmental impact is essential. It's not enough to focus solely on savings. Awareness of sustainability practices is growing. This creates an opportunity for improvement. Strive to make informed choices in your next project.