In recent years, the construction industry has increasingly favored Hot Dip Pipe due to its durability and corrosion resistance. According to a report by the American Society of Civil Engineers, the demand for high-quality piping solutions has surged by 30% over the last five years. This shift highlights the importance of choosing the right materials for long-lasting infrastructure. Industry expert Dr. Emily Chen states, “Hot Dip Pipe offers unmatched longevity compared to traditional piping options.”

Hot Dip Pipe's unique galvanization process provides a robust barrier against environmental factors. This feature is especially crucial for projects in regions with severe weather or corrosive soil conditions. A recent survey indicated that 78% of construction managers reported fewer maintenance issues when using Hot Dip Pipe in their projects. However, some contractors still have concerns about initial costs and availability.

While Hot Dip Pipe presents a compelling option, it also creates challenges. Supply chain fluctuations can delay projects, leaving some teams to reconsider material choices. A balance must be struck between cost and quality. To foster better decision-making, ongoing discussions in the industry are essential, acknowledging both benefits and drawbacks of Hot Dip Pipe.

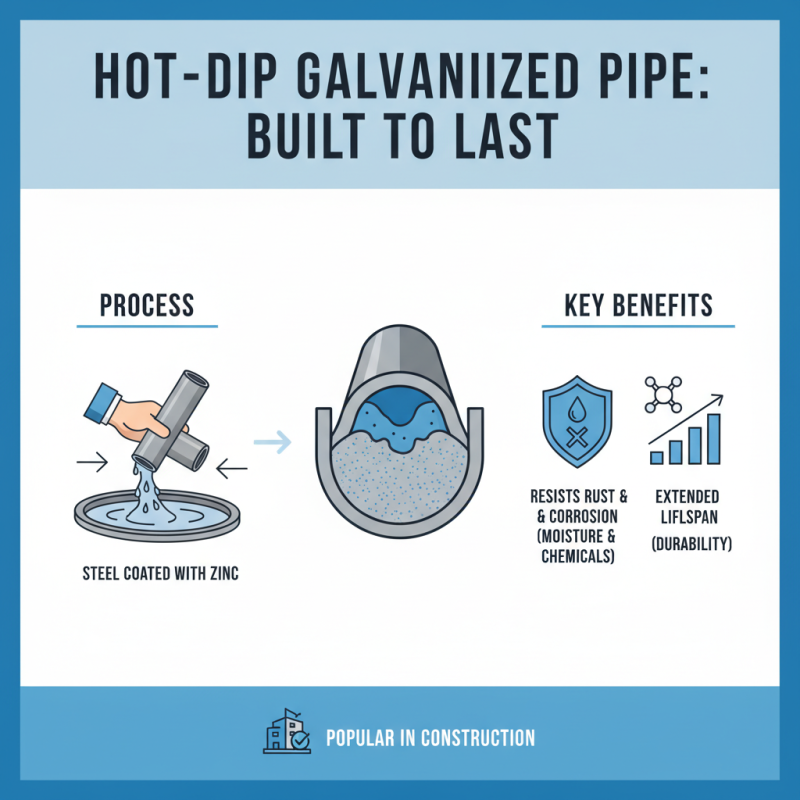

Hot dip galvanized pipe has gained popularity in construction projects due to its impressive durability. The galvanization process involves coating steel with zinc. This helps to prevent rust and corrosion, extending the pipe's lifespan significantly. Many constructions face harsh weather conditions. The protective layer of zinc acts as a barrier against moisture and chemicals.

Another noticeable benefit is cost-effectiveness. Though the initial cost of hot dip galvanized pipe may be higher, its long-term savings are substantial. Fewer replacements and repairs can lead to reduced maintenance costs over time. Additionally, its strength provides better structural integrity for various applications, from water lines to structural frameworks.

However, it is essential to reflect on the installation process. Poor practices can undermine the advantages of hot dip galvanized pipe. If not installed correctly, the pipes may still face issues in the future. Ensuring proper installation and regular inspections is vital. Construction teams must prioritize training and quality assurance to maximize the benefits of this material.

Hot dip pipes are increasingly popular in construction projects due to their durability. These pipes undergo a galvanization process. This process involves dipping steel pipes in molten zinc. As a result, they develop a thick protective layer. This layer acts as a barrier against corrosion.

Corrosion resistance is crucial in many environments. Hot dip pipes can withstand harsh chemicals and moisture. They often last longer than traditional pipes. Many engineers trust them for underground and above-ground applications. However, despite their advantages, these pipes can still face challenges. If the protective layer gets damaged, rust can form. Regular inspections are necessary to ensure longevity.

In terms of maintenance, the initial investment may feel high. Yet, the lifetime benefits often outweigh the costs. Projects that prioritize cost may overlook these aspects. This oversight can lead to problems down the road. Balancing budget and quality is essential for any construction plan. Investing in hot dip pipes can ultimately save time and resources.

Hot dip galvanized pipes are becoming a preferred choice in construction projects. Their durability and corrosion resistance are noteworthy. These pipes undergo a special coating process that enhances their lifespan. Over time, this helps reduce maintenance costs significantly.

The cost-effectiveness of hot dip galvanized pipes becomes evident when comparing them to other materials. While the initial investment may be relatively high, the long-term savings often outweigh these costs. For instance, these pipes can last for decades, minimizing the need for replacements. Maintenance can be less frequent and less expensive too.

Tip: Always consider the environmental factors in your area. Depending on the climate, hot dip pipes may provide better durability. Analyze previous projects to measure performance. These insights can aid future decisions. It's essential to balance cost with quality. Sometimes the cheapest option may lead to higher expenses later. Reflecting on past choices is crucial for improvement.

Hot dip pipes are becoming a preferred choice in various construction projects. They are notably used in infrastructure, water supply, and industrial applications. According to a report by the Global Pipe Market, the demand for hot dip galvanized pipes is expected to grow at a rate of 5% annually. This growth can be attributed to their durability and resistance to rust and corrosion.

In infrastructure development, hot dip pipes are utilized for water transport systems. They ensure safe and reliable delivery of potable water. A study by the World Health Organization highlights that galvanized pipes can last for over 50 years, greatly minimizing replacement costs. However, installation can be complex and requires skilled labor.

In the industrial sector, hot dip pipes serve in chemical processing plants and oil refineries. They are resistant to harsh chemicals and environmental conditions. The International Energy Agency cites that using high-quality pipes can reduce leaks and environmental hazards. Still, challenges exist, such as the risk of inadequate fitting and the need for regular maintenance. These factors remind us of the importance of continuous improvement in installation practices.

When considering hot dip pipes for construction projects, installation is key. Proper installation ensures longevity and durability. Ensure that surfaces are clean and dry before installation. This helps avoid any potential issues during the project. Workers must use the correct tools and techniques for a secure fit. It is vital to follow guidelines and best practices during this process.

Maintenance is also crucial to the performance of hot dip pipes. Regular inspections can identify corrosion or damage early on. Visual checks should be conducted at least twice a year. Pay attention to joints and connections; these are often weak points. Cleaning is important as well. Accumulation of dirt and debris can lead to problems.

While hot dip pipes are sturdy, they are not invincible. Weather conditions can wear them down over time. It’s important to stay mindful of potential flaws. Sometimes, maintenance can be overlooked in busy schedules. Ignoring it can result in costly repairs in the future. Small steps today can lead to better performance tomorrow.

| Dimension | Details |

|---|---|

| Corrosion Resistance | Hot dip pipes are coated with zinc which provides superior corrosion resistance compared to traditional pipes. |

| Durability | The hot dip process enhances the longevity and strength of the pipes, making them suitable for harsh conditions. |

| Installation Ease | Hot dip pipes often come with standardized fittings that simplify installation processes on-site. |

| Maintenance | Less maintenance is required due to their resistance to rust and other environmental factors. |

| Cost-Effectiveness | The initial investment in hot dip pipes can be offset by reduced maintenance costs and greater lifespan. |