When embarking on a new construction project, selecting the right materials can make all the difference in durability and aesthetic appeal. One material that has gained significant attention in recent years is the Galvalume Coil, known for its exceptional corrosion resistance and longevity. Industry expert Dr. Jane Smith, a leading materials scientist, emphasizes the importance of informed choices, stating, "Choosing the right Galvalume Coil not only enhances the lifespan of your structure but also ensures optimal energy efficiency and cost-effectiveness."

Understanding the distinct characteristics of Galvalume Coil is essential for architects, builders, and homeowners alike. These coils, composed of a unique aluminum-zinc alloy, offer advantages over traditional galvanized steel, including improved resistance to rust and UV degradation. As construction demands evolve, so does the need for innovative materials that can withstand the test of time. By delving into the various thicknesses, finishes, and coatings available in Galvalume Coil offerings, project stakeholders can better align their selections with specific project requirements.

In conclusion, the choice of Galvalume Coil can significantly impact the overall performance of a project. By consulting with industry experts and thoroughly evaluating the options available, decision-makers can pave the way for successful outcomes that balance functionality and design.

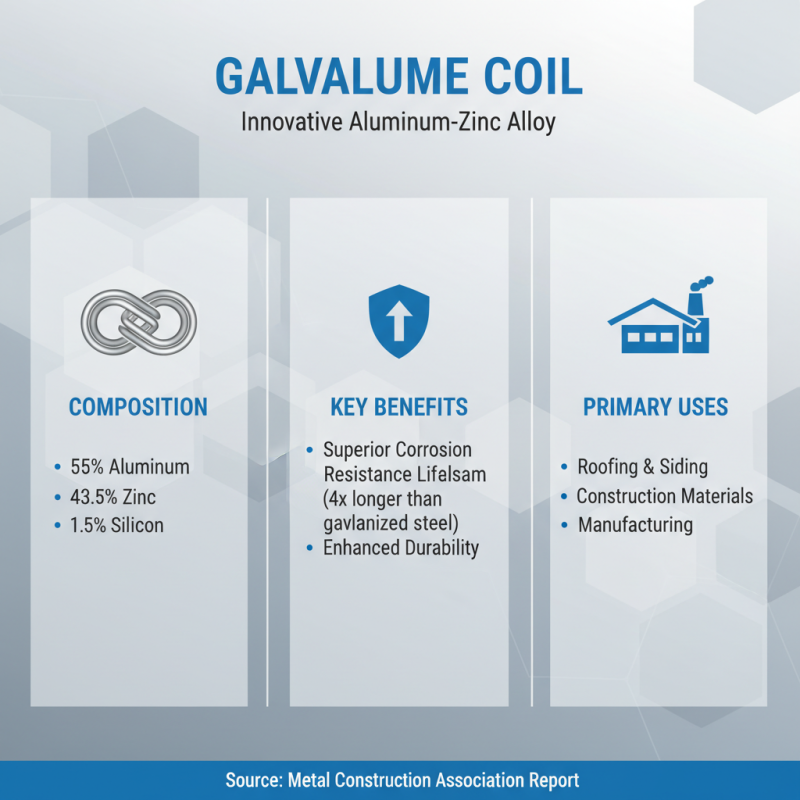

Galvalume coil, an innovative blend of aluminum and zinc, has garnered significant attention in the construction and manufacturing industries. This unique composition typically consists of 55% aluminum, 43.5% zinc, and 1.5% silicon, offering properties that enhance its durability and lifespan. According to a report by the Metal Construction Association, Galvalume can provide corrosion resistance that can last up to four times longer than traditional galvanized steel, making it an optimal choice for roofing and siding applications in various environments.

Understanding the characteristics of Galvalume coil is crucial for making informed decisions in your next project. Its smooth surface and high reflectivity contribute not only to aesthetic appeal but also to energy efficiency by reflecting sunlight and reducing heat absorption. The coil's ability to withstand harsh conditions, coupled with its low maintenance requirements, aligns with industry trends that prioritize sustainable and cost-effective building materials. A study by the American Iron and Steel Institute indicates that structures using Galvalume demonstrate reduced energy consumption, benefiting both the environment and the bottom line.

Tips for selecting the right Galvalume coil include evaluating the specific environmental factors of your project, such as humidity and exposure to chemicals, which can impact material longevity. Additionally, considering the coil’s thickness and coating weight is essential, as these factors contribute to its overall performance. Always consult with material specifications aligned with industry standards to ensure optimal choice and application.

When selecting the right Galvalume coil for your project, several key factors must be considered to ensure optimal performance and longevity. One of the foremost factors is the coating weight, which is critical in determining the coil's corrosion resistance and durability. According to industry data, a typical minimum specification is G90, which means the surface has a zinc coating of 0.90 ounces per square foot on both sides. For harsher environments, a higher coating weight may be necessary to provide adequate protection.

Another important consideration is the manufacturing process, specifically the thickness of the base steel used in the coil. The American Iron and Steel Institute recommends a minimum thickness of 26 gauge for residential roofing applications to withstand wind loads and potential impact damage. Additionally, the intended application—be it roofing, siding, or other uses—will dictate specific performance requirements, including thermal efficiency and paint adhesion characteristics. Research indicates that well-chosen Galvalume coils can improve the energy efficiency of buildings by reflecting solar radiation, potentially reducing cooling costs by up to 15%, a significant factor for sustainable construction projects.

Finally, the aesthetic finish of Galvalume coils plays a crucial role in selection, as visual appeal can enhance the overall design. Whether opting for a pre-painted coil or leaving it in its natural state, understanding the available finishes and their long-term performance will help in making a more informed choice. It’s essential to access technical specifications and performance data that align with your project's requirements to achieve the best results.

Galvalume coil is increasingly becoming a preferred choice in diverse construction applications due to its impressive durability and resistance to corrosion. According to a report by the American Iron and Steel Institute, the lifespan of Galvalume-coated steel can exceed 40 years, making it a cost-effective solution for buildings and structures exposed to harsh environmental conditions. Its unique composition, featuring a combination of zinc and aluminum, provides superior protection against rust and wear, which is essential for roofing, siding, and other exterior elements in both commercial and residential projects.

In the construction industry, Galvalume coil is particularly valued in the manufacturing of metal roofing systems. Data from the Metal Roofing Alliance indicate that metal roofs, many of which use Galvalume materials, can reflect solar energy, thereby reducing cooling costs by up to 25%. Furthermore, Galvalume’s lightweight nature allows for easier handling and installation, making it an optimal choice for construction teams looking to enhance efficiency. The versatility of Galvalume extends to industrial buildings, agricultural structures, and even residential homes, demonstrating its adaptability across various construction environments while maintaining aesthetic appeal and functional performance.

When selecting the right Galvalume coil for your next project, it's essential to understand how it compares to alternative metal coatings such as galvanized steel and aluminum. Galvalume, which combines aluminum and zinc, offers superior resistance to corrosion, particularly in environments with high humidity or salt exposure. According to a report from the Metal Construction Association, Galvalume can last up to 2 to 6 times longer than traditional galvanized steel, which typically has a lifespan ranging from 10 to 20 years, depending on the environment. This longevity makes Galvalume an appealing option for projects where durability is critical.

Furthermore, Galvalume's reflective properties contribute to energy efficiency by reducing heat absorption, a key consideration in regions with high cooling demands. In contrast, while aluminum also provides excellent corrosion resistance, it lacks the strength-to-weight ratio found in Galvalume. A study from the American Iron and Steel Institute highlights that Galvalume can withstand significant impact without compromising its structural integrity, making it well-suited for roofing applications and other structural components. Thus, when evaluating metal coatings, understanding the performance factors, including lifespan, corrosion resistance, and energy efficiency, is crucial in making the best choice for your project.

| Metal Coating Type | Corrosion Resistance | Lifespan (Years) | Cost (per square foot) | Weight (lbs/sq. ft) | Common Applications |

|---|---|---|---|---|---|

| Galvalume | Excellent | 20+ | $0.90 | 0.75 | Roofs, siding, HVAC |

| Galvanized Steel | Good | 10-20 | $0.80 | 0.95 | Fencing, agricultural buildings |

| Aluminum | Very Good | 30+ | $1.50 | 0.5 | Marine, architectural applications |

| Zinc-Coated Steel | Moderate | 5-15 | $0.75 | 1.0 | Pipes, HVAC systems |

When it comes to maintaining Galvalume coil products, regular inspection and cleaning are essential to prolong their lifespan. Over time, dirt, debris, and natural elements can accumulate on the surface, potentially leading to corrosion. It is advisable to clean the coils with a soft brush or cloth and a mild detergent solution. Avoid using abrasive cleaners or tools that might scratch the surface, as this can compromise the protective coating. Additionally, if any scratches or chips are detected, it is crucial to address them promptly to prevent rust formation.

Another important maintenance tip is to ensure adequate drainage around the Galvalume products. Standing water or trapped moisture can lead to accelerated deterioration. Installing proper drainage systems or ensuring a sloped landscape can help mitigate this risk. Furthermore, inspecting the seals and joints for wear and tear can significantly contribute to the overall durability of the installation. By following these maintenance practices, you can enhance the longevity and performance of your Galvalume coil products, ensuring they remain in optimal condition throughout their service life.