Choosing the right Copper Strip for your projects is crucial. With various types available, the decision can be overwhelming. Copper Strips vary in thickness, width, and purity. It's essential to know what you need before making a choice.

Consider your project's specific requirements. A thin Copper Strip might be more suitable for electronics. Thicker options may serve better in construction. Each project could benefit from different characteristics of Copper Strip. Understanding your needs will guide your decision.

Sometimes, making the wrong choice is easy. You may overlook details like tensile strength or conductivity. Reflecting on past experiences can improve future selections. Proper research will definitely yield better results. Take your time and assess your options carefully.

When choosing a copper strip for your project, it's essential to understand the different types available. Copper strips vary in width, thickness, and finish. These factors can greatly influence your project's outcome. Some common types include bare copper strips, tinned copper strips, and plated variations. Each type serves specific functions, so identifying your needs is crucial.

Consider the intended application of your copper strip. For electrical work, bare copper strips offer excellent conductivity. Tinned options resist corrosion, making them suitable for outdoor use. If the aesthetic is important, polished strips may be more appealing.

Tips: Always test the copper strip's flexibility to ensure it works for your project. You might find that a thicker strip is too rigid for certain designs. Measure your project's requirements carefully. Sometimes, a smaller width might suffice for your needs. Keep in mind your project's environment; humidity can affect copper's longevity. Reflect on these factors to avoid future problems.

| Type of Copper Strip | Width (mm) | Thickness (mm) | Application | Corrosion Resistance | Electrical Conductivity (MS/m) |

|---|---|---|---|---|---|

| Electrolytic Copper | 10 | 0.5 | Wiring and Electronics | Moderate | 58.1 |

| Copper Alloy | 20 | 1.0 | Fittings and Valves | High | 56.0 |

| Tinned Copper | 15 | 0.8 | Marine and Outdoor Applications | Excellent | 58.0 |

| Oxygen-Free Copper | 25 | 1.5 | High-Fidelity Audio | Good | 61.0 |

| Copper-Nickel | 30 | 2.0 | Marine Hardware | Very High | 57.0 |

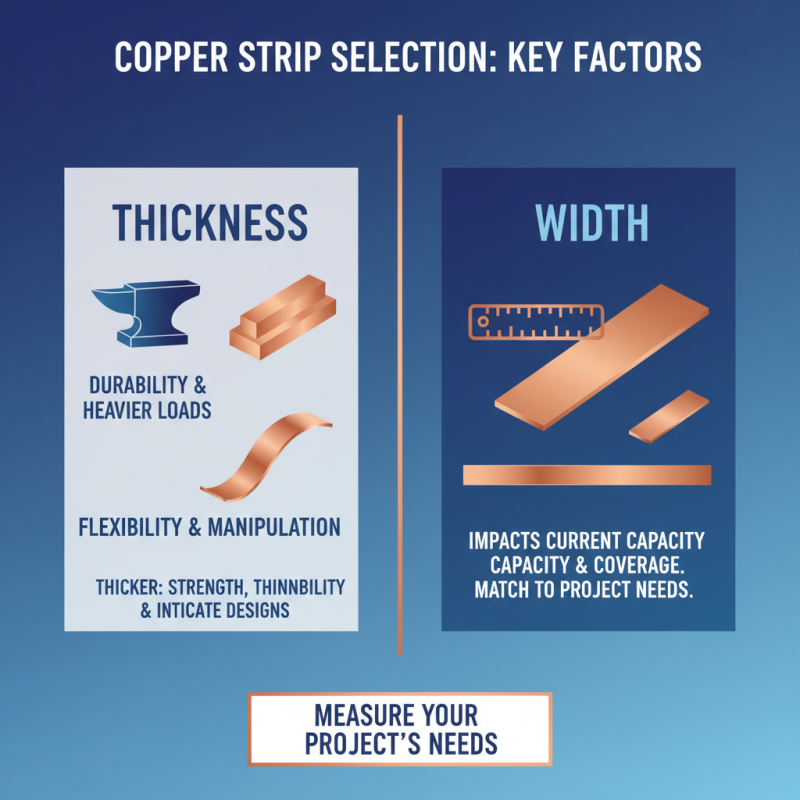

When selecting copper strips, thickness and width are crucial specifications. The thickness of the strip impacts its durability and flexibility. A thicker strip can support heavier loads, while a thinner one is easier to manipulate. For intricate designs, a thinner strip may be required. Measure your project's needs carefully.

Width is equally important. Wider strips can cover larger surfaces but may be harder to handle. On the flip side, narrower strips offer precision but require more time to install. Think about the scale of your project. A miscalculated width can lead to unnecessary waste and complications.

Consider the environment where your copper strips will be used. Will they be exposed to harsh conditions? This might demand thicker options. Reflect on whether the copper will be visible or hidden. Aesthetic choices can also guide your decision on dimensions. Evaluating these aspects ensures you select the right copper strips for your needs.

When selecting the right copper strip for your projects, understanding the properties of various copper alloys is crucial. Copper strips come in different alloys, each suited for specific applications. For instance, C11000, the purest form of copper, boasts excellent conductivity. It is ideal for electrical applications where performance is key. However, it lacks strength compared to other alloys.

C26000, or brass, offers a balance of strength and conductivity. This alloy is commonly used in decorative applications and plumbing fixtures. According to industry data, brass also resists corrosion better than pure copper, making it a practical choice for outdoor use. Keep in mind that while it is durable, it may tarnish over time.

Tip: Always assess the environment where the copper will be used. If it's exposed to harsh conditions, opt for a more resilient alloy.

C44300 combines copper with tin, enhancing corrosion resistance. This alloy is perfect for marine applications. However, it costs more than standard copper. It's essential to factor in your budget alongside performance needs. Overlooking cost may lead to overspending on projects.

Tip: Compare the lifespan of different alloys. Sometimes, investing more upfront saves money in the long run by reducing maintenance costs.

When selecting copper strips for your projects, consider the cost factors carefully. Prices can vary significantly based on thickness and purity. Suppliers might offer competitive pricing, but ensure you assess the quality thoroughly. Opting for lower prices can sometimes lead to subpar materials. Investigate multiple suppliers to find the best balance between cost and quality.

Tips: Always request samples before making larger purchases. This ensures you evaluate the material firsthand. Check if the supplier provides certificates of authenticity for their copper strips. It’s crucial to understand the thickness specifications. Sometimes, a slightly thinner strip may suffice, cutting costs while meeting your project needs.

Packaging and shipping costs also play a role. Some suppliers charge extra for delivery, effectively increasing your total expenditure. Watch for any hidden fees that may not be immediately obvious. Make sure to weigh the total costs, including these additional factors. It's easy to overlook small details, but they can significantly impact your budget.

When considering copper strips for projects, installation is crucial. Proper installation can extend the lifespan of the copper. A report from the Copper Development Association indicates that well-installed copper strips can last over 50 years. Factors such as temperature changes and moisture levels can affect this life expectancy. It is essential to ensure proper sealing and mounting techniques.

Maintenance is another key aspect. Routine checks for corrosion and wear are necessary. A study published in the Journal of Materials Science suggests that copper can corrode when exposed to certain environments. Regular cleaning with mild solutions can help maintain the appearance and integrity of copper strips. However, over-cleaning can sometimes cause unintended damage.

Using protective coatings can add longevity to your project. These coatings can shield against environmental stressors. Yet, choosing the right coating is a challenge. Some coatings may degrade faster than anticipated. Careful product evaluation is vital for optimal performance.