When embarking on a project that requires a durable material, the choice of a galvanized plate is crucial. Galvanized plates are steel items coated with zinc to prevent rust. According to industry reports, the global market for galvanized steel is projected to reach USD 232.3 billion by 2027, reflecting a growing demand for corrosion-resistant materials.

Yet, selecting the right galvanized plate involves careful consideration of several factors. Thickness, coating weight, and surface finish all play significant roles in performance. For example, a heavier coating can extend the lifespan of your project, but it may also increase costs. Additionally, not every galvanized plate meets the same standards; some may lack adequate protection against certain environmental conditions.

While many assume all galvanized plates are of equal quality, this is not the case. Poorly manufactured plates can lead to premature failure. It is essential to reflect on these factors and select wisely. Understanding the specifics can help avoid complications during installation and long-term use. Your project's success depends on making informed decisions regarding galvanized plates.

Galvanized plates are essential materials in various projects. They are made of steel coated with zinc to prevent rust. This coating provides a protective barrier that extends the lifespan of the metal. Galvanized plates resist corrosion, making them ideal for outdoor applications. They are commonly used in construction, automotive, and manufacturing industries.

These plates serve multiple purposes. For instance, they can be used as roofing, siding, or as supports for structures. They are also prevalent in crafting and DIY projects. However, not all galvanized plates are created equal. Different thicknesses and coatings can affect performance. Choosing the right type requires an understanding of the specific needs of your project. Some coatings may not hold up well in extreme conditions.

It's worth noting that improper choices can lead to setbacks. An insufficiently coated plate may rust quickly. On the other hand, using a thicker plate than necessary can result in unnecessary weight and cost. Evaluating the environment and application is crucial. Consider factors such as temperature fluctuations and exposure to moisture before deciding. Choosing wisely can make a significant difference in the outcome of your project.

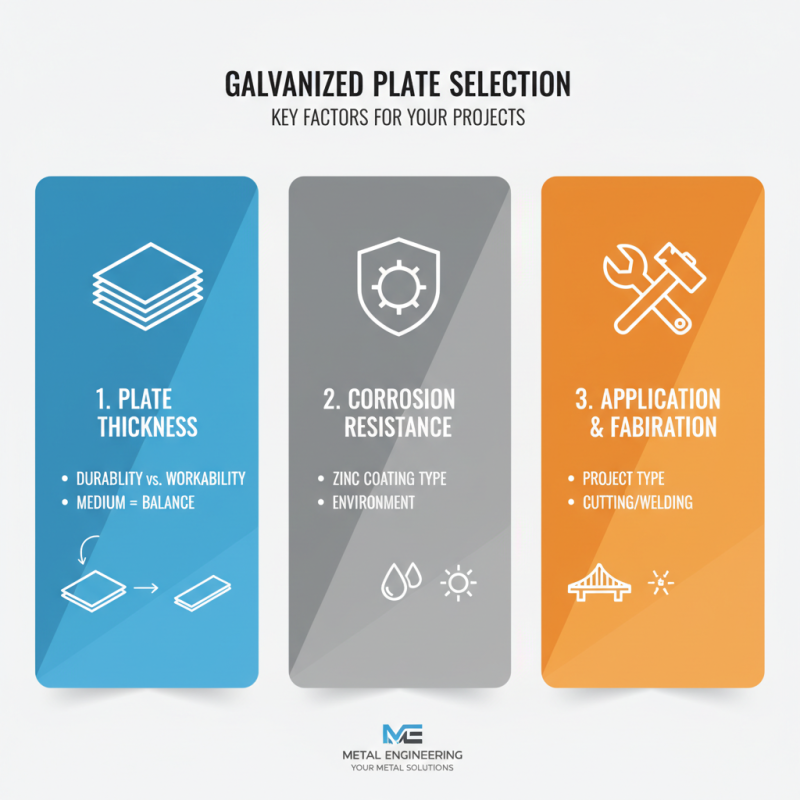

When selecting galvanized plates, understanding the types of coatings is essential. Hot-dip galvanizing is a common method, providing a thick layer of zinc. This method enhances corrosion resistance significantly. It suits outdoor structures and marine applications. On the other hand, electro-galvanized plates have a thinner coating. They are ideal for indoor use where exposure to moisture is limited. While they are less resilient to harsh conditions, they offer a smoother finish and better paint adhesion.

Thickness is another critical factor. Standard galvanized plates typically come in 0.5 mm to 3 mm thicknesses. Thicker plates provide more durability for heavy-duty applications. However, they may be challenging to work with during installation. It’s important to weigh the benefits of durability against the ease of handling. For lighter uses, thinner plates reduce weight but sacrifice some resistance to impacts. Reflecting on your project’s specific requirements can guide you toward the best choice. Consider not only the environmental factors but also how the materials will interact with their surroundings.

| Type of Galvanized Plate | Coating Type | Thickness (mm) | Corrosion Resistance (Years) | Common Applications |

|---|---|---|---|---|

| Electro-galvanized Plate | Electroplated Zinc | 0.5 - 1.2 | 5 - 10 | Indoor Applications |

| Hot-dip Galvanized Plate | Hot-dipped Zinc | 1.0 - 5.0 | 20 - 50 | Outdoor and Harsh Environments |

| Pre-galvanized Plate | Pre-coated Zinc | 0.4 - 2.0 | 10 - 20 | Light-Duty Applications |

| Zinc-Aluminum Coated Plate | Zinc-Aluminum Alloy | 0.8 - 3.0 | 15 - 30 | Automotive and Construction |

| Stainless Steel Galvanized Plate | Passivated Zinc | 1.5 - 6.0 | 25+ | Marine and Chemical Industries |

When selecting galvanized plates for your projects, several key factors come into play. The first is the thickness of the plate. Thicker plates provide better durability but can be harder to work with. Always consider what your project demands. A medium thickness often offers a balance.

The coating thickness is another important aspect. This determines the corrosion resistance. A heavier coating will protect against rust for longer periods. However, keep in mind that it can affect welding quality. Adjust your expectations based on the project specifics.

**Tips:** Always measure your project’s requirements before making a decision. Understand if you need flexibility or rigidity.

Quality is essential too. Not all galvanized plates are created equal. Some may have inconsistent coatings and defects. Inspect samples when possible. Remember, the choice of galvanized plates can impact your project's longevity.

**Tips:** Look for certification stickers on plates for assurance. It helps validate quality compliance. You can also consult with local suppliers for advice.

Galvanized plates play a crucial role in various industries. They provide durability and resistance to corrosion, making them ideal for construction, automotive, and infrastructure projects. In the construction industry, galvanized plates support structures and ensure longevity. They withstand harsh weather conditions and provide essential protective measures against corrosion.

In the automotive industry, these plates are found in vehicle bodies. They enhance strength without adding significant weight. This is essential for efficiency and performance. Galvanized plating also helps in resisting rust and extending the life of automotive parts. It’s important to select the right thickness, as this can affect both performance and aesthetics.

Tips: When choosing a galvanized plate, consider its intended use. Thickness, coating type, and finish can greatly differ. Always check for compatibility with other materials. You don’t want corrosion to spread from one component to another. Remember, not all galvanized plates are created equal; some are better suited for specific applications.

In infrastructure, these plates are widely used for bridges and fences. They help create stability and promote safety. However, proper maintenance is key. Some galvanized plates may deteriorate faster under certain conditions. Always assess environmental factors. A little caution can save you from costly repairs down the line.

Maintaining galvanized plates is essential for their longevity. These plates are commonly used due to their corrosion resistance. However, they still require care to avoid rust and deterioration. Ensure regular inspections for any signs of damage. Check for scratches or exposed areas where zinc coating has worn off.

Cleaning is another crucial step. Use mild soap and water to remove dirt and debris. Avoid harsh chemicals as they can damage the surface. A soft brush or cloth can be effective without scratching the galvanized finish. After cleaning, inspecting for additional protective measures can extend the lifespan of the plate significantly.

Environmental factors play a crucial role as well. In coastal areas, salt can accelerate corrosion. In such cases, consider applying a protective coating. Be mindful of moisture and avoid storing galvanized plates in damp conditions. Awareness and proactive maintenance can significantly improve the duration of your galvanized plates in any project.