Galvalume Coil is an innovative steel product that has revolutionized the construction and manufacturing industries with its unique properties. Composed of a zinc-aluminum alloy coating, Galvalume Coil offers superior corrosion resistance and durability compared to traditional galvanized steel. Its remarkable strength-to-weight ratio makes it an ideal choice for a variety of applications, including roofing, siding, and metal building systems. As a result, it has become increasingly popular among builders and manufacturers seeking sustainable and long-lasting material solutions.

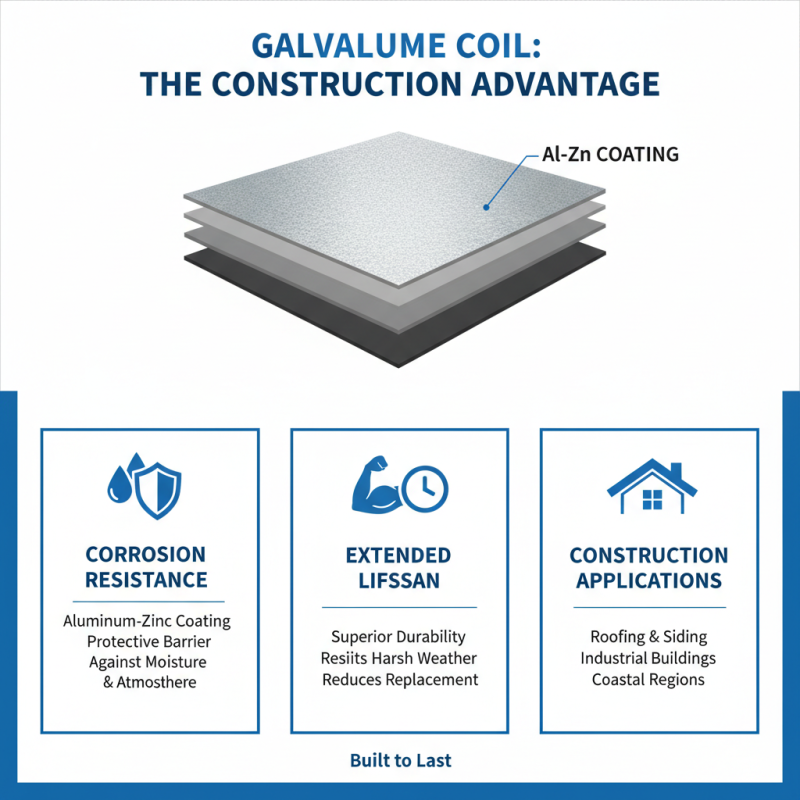

In the realm of construction, Galvalume Coil is widely utilized due to its aesthetic versatility and capability to withstand harsh environmental conditions. Its reflective surface not only contributes to energy efficiency by minimizing heat absorption but also enhances the visual appeal of a structure. Similarly, in manufacturing, Galvalume Coil serves as a critical component in automotive, appliance, and HVAC industries—where its resilience and ease of fabrication play a crucial role in producing high-quality products.

The significance of Galvalume Coil extends beyond its physical attributes; it also represents a sustainable approach to material use in construction and manufacturing. By selecting Galvalume Coil, professionals can contribute to reducing environmental impact while ensuring the long-term performance and aesthetic integrity of their projects. Therefore, understanding the properties and applications of Galvalume Coil is essential for anyone looking to make informed decisions in the building and manufacturing sectors.

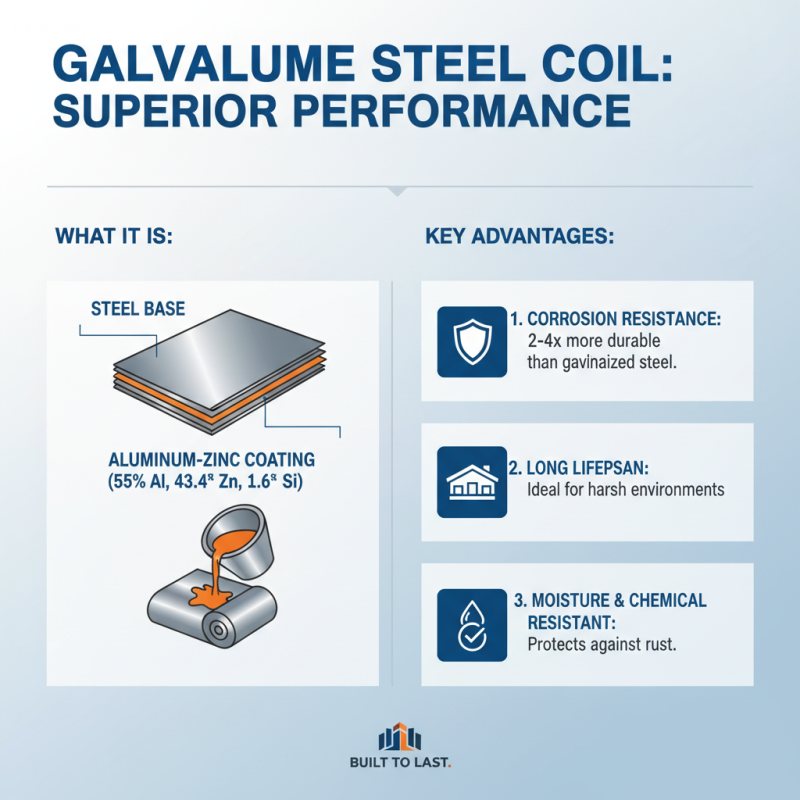

Galvalume coil, an innovative metal product, combines the corrosion resistance of aluminum with the durability of zinc. It typically consists of a base steel coated with a unique mixture of approximately 55% aluminum, 43.5% zinc, and 1.5% silicon. This unique composition provides the material with an exceptional lifespan—often exceeding 25 years in various environments, according to data from industry reports. Galvalume's reflective properties also enhance energy efficiency by reducing heat absorption, making it a favored choice in sustainable building solutions.

In construction and manufacturing, Galvalume coils are widely utilized for roofing, siding, and various sheet metal applications due to their robust performance. A recent market analysis revealed that the global demand for Galvalume-coated products increased by 12% over the last year, driven primarily by a surge in green building initiatives and the push for energy-efficient materials. This growth highlights the versatility of Galvalume in both residential and commercial projects, where long-lasting durability is imperative.

Tips: When selecting Galvalume for your projects, consider the environmental conditions it will face—this can greatly affect its longevity. Always ensure compatibility with other materials to avoid galvanic corrosion. Additionally, investing in high-quality Galvalume can provide significant savings in maintenance and replacement costs over time.

Galvalume coil is a steel product that is coated with a combination of zinc, aluminum, and silicon, providing exceptional corrosion resistance and durability. The typical composition of Galvalume includes approximately 55% aluminum, 43.5% zinc, and 1.5% silicon by weight. This unique alloying results in a coating that offers superior protection compared to traditional galvanized steel. The aluminum content contributes to the formation of a dense and protective oxide layer, which enhances its performance against corrosion and high-temperature environments.

The coating process of Galvalume is accomplished through a continuous hot-dipping technique. In this process, a steel substrate is passed through a bath of molten zinc-aluminum alloy, allowing the metal to adhere firmly to the surface. This method ensures a uniform coating thickness and promotes excellent adhesion between the layer and the underlying steel. Following the coating, the Galvalume coils undergo various treatments to improve their surface finish and prepare them for further applications in construction and manufacturing. The result is a product that not only showcases excellent physical and mechanical properties but also lends itself well to various fabrication processes, making it a preferred choice for a variety of industries.

Galvalume coil, known for its unique coating of aluminum and zinc, possesses several key properties that make it particularly suitable for construction applications. One of the most notable features is its excellent corrosion resistance. The aluminum in the coating provides a protective barrier against moisture and atmospheric conditions, significantly extending the lifespan of roofing and siding materials. This durability is crucial in regions with harsh weather conditions, where traditional steel may fail more rapidly.

In addition to corrosion resistance, Galvalume coil exhibits remarkable thermal efficiency. The reflective properties of its surface help in reducing heat absorption, leading to lower energy costs in buildings. This characteristic makes it an attractive choice for energy-efficient construction, contributing to improved indoor comfort and reduced reliance on air conditioning systems. Furthermore, Galvalume’s lightweight nature simplifies the installation process, allowing for quicker construction timelines and reduced labor costs, which are advantageous for both manufacturers and builders. Overall, these properties make Galvalume coil a versatile and effective choice in the construction and manufacturing industries.

Galvalume coil, an alloy of aluminum, zinc, and silicon, has gained prominence in the manufacturing industry due to its exceptional corrosion resistance and durability. This unique coating composition typically comprises 55% aluminum, 43.5% zinc, and 1.5% silicon, enhancing the steel’s lifespan dramatically. According to a report by the American Galvanizers Association, structures utilizing Galvalume can expect a service life that is two to six times greater than that of traditional galvanized steel, making it an economically wise choice for various applications.

In the manufacturing sector, Galvalume coil is widely employed in the production of roofing materials, wall panels, and other structural components. Its excellent thermal performance contributes to energy efficiency in buildings, with studies indicating a potential reduction in energy costs by as much as 20%. Additionally, the automotive industry utilizes Galvalume for parts and components that require both durability and aesthetic appeal, showcasing its adaptability across different manufacturing processes. The versatility and longevity of Galvalume coil make it an integral material in sectors ranging from construction to automotive manufacturing, driving advancements in production techniques and sustainability.

Galvalume coil is a coated steel product that combines the strength of traditional steel with a unique coating of aluminum and zinc. This innovative material offers several comparative advantages over traditional steel coatings, particularly in terms of durability and corrosion resistance. The primary benefit of Galvalume is its ability to withstand harsh environmental conditions, making it an ideal choice for construction and manufacturing applications where exposure to moisture and corrosive elements is a concern. Unlike conventional galvanized coatings, which may degrade over time, Galvalume maintains its protective properties much longer, thereby extending the lifespan of structures.

In addition to enhanced longevity, Galvalume coil also boasts superior heat resistance. The aluminum content in the coating reflects heat more efficiently, reducing the risk of thermal degradation. This property is particularly beneficial in industries where temperature fluctuations are common, ensuring that the material retains its integrity over prolonged periods. Furthermore, the aesthetic appeal of Galvalume is noteworthy, as it can be easily finished or painted, providing versatility in design without compromising its functional qualities. This combination of durability, heat resistance, and aesthetic flexibility makes Galvalume coil a preferred choice for modern construction and manufacturing needs.