Metal sheets are essential in various industries, from construction to manufacturing. According to a report from TechNavio, the global metal sheet market is expected to grow by 4.5% each year, driven by increasing demand in automotive and aerospace sectors. Industry expert Dr. Lisa Hargrove notes, "Choosing the right metal sheet can greatly influence project outcomes."

There are numerous types of metal sheets available, each with unique properties. Aluminum, steel, and copper sheets rank among the most popular choices. Their versatility allows for a range of applications, from roofing to packaging. However, selecting the right type can be challenging. For instance, stainless steel is known for its corrosion resistance, but it can be more expensive than other options.

Despite their advantages, some metal sheets may come with drawbacks. For example, aluminum is lightweight but may lack the strength needed for certain applications. Reflecting on these aspects can lead to more informed decisions in your projects. Understanding the types of metal sheets and their implications is crucial for achieving the desired results.

When selecting metal sheets for your projects, understanding the variety available is crucial. Aluminum sheets are lightweight and corrosion-resistant. They are perfect for applications requiring durability without extra weight. Steel sheets, known for their strength, come in various grades. They are ideal for construction and automotive projects. However, they can rust if not properly treated.

Stainless steel sheets offer a sleek, modern look. They resist corrosion and staining, making them popular in kitchen designs. Copper sheets also deserve mention; they bring a unique aesthetic to any project. However, their cost can be a significant factor. Galvanized steel sheets provide durability through a protective zinc coating. But, this coating can wear away over time, leading to rust.

Each metal sheet type has its pros and cons. Choices depend on budget, aesthetic needs, and functional demands. It's essential to reflect on these aspects before finalizing your decisions. Sometimes, the most popular choice may not be the right one for you, and that's okay. Balancing practicality with creativity is key.

Aluminum sheets have gained popularity in various projects due to their lightweight nature. They are easy to handle and transport. This makes them ideal for both small and large-scale applications. The reduced weight can often lead to cost savings in shipping and labor. However, it is important to consider that lighter materials may sometimes compromise durability.

Corrosion resistance is another significant advantage of aluminum sheets. They naturally form a protective oxide layer that inhibits rust and degradation. This feature makes them suitable for outdoor projects or environments with moisture. Still, it's crucial to ensure proper sealing or coating in certain conditions. There can be challenges in maintaining their appearance over time, especially if exposed to harsh elements.

Aluminum sheets also offer versatility in design and application. They can be easily cut, shaped, or welded for various uses. From architectural projects to DIY crafts, the possibilities are numerous. However, one must remain cautious about the thickness and types of aluminum. Not all aluminum sheets provide the same strength or durability. This variability can lead to unanticipated issues in performance.

When it comes to metal sheets, steel sheets stand out. They offer strength and versatility unmatched by other materials. These sheets can be used in various applications. From construction to automotive industries, their reliability is key. Steel sheets resist deformation under stress. They can sustain heavy loads without compromising integrity.

In architectural projects, steel sheets provide structural support. Their surfaces can be treated for aesthetic appeal. This characteristic allows for a blend of functionality and design. However, not every project demands steel. The thickness and grade of the sheet matter greatly. Thick sheets might be overkill for lighter applications. It's essential to assess the needs carefully.

Consider the environment where the project will take place. Steel can corrode if not properly treated. This risk must be weighed against its strength. It's important to match materials to their intended use. Misjudgments in material selection can lead to structural failures. Careful planning and reflection on the project requirements are crucial.

Copper sheets are a fantastic choice for various projects. They offer a remarkable combination of aesthetic appeal and practical features. The warm, reddish hue of copper adds a sophisticated touch to any design. This metal ages beautifully, developing a unique patina over time. Some people love this change, while others may prefer the shiny finish. It’s a matter of taste.

Besides their beauty, copper sheets are known for excellent conductivity. They conduct electricity very well, making them ideal for electrical projects. However, working with copper can be tricky. The metal is softer than others, so it bends and scratches easily. Care must be taken to avoid damage during handling and installation. Also, the cost can be higher than alternatives; this may limit your options.

Many artists and builders choose copper for its versatility. It can be cut, shaped, and soldered with relative ease. However, some skills are required to achieve clean cuts and smooth edges. Mistakes can lead to wasted material. Assess your skills before diving into a copper project. Understanding its properties will help you make the most of this stunning material.

| Metal Type | Aesthetic Appeal | Conductivity | Applications |

|---|---|---|---|

| Copper | High | Excellent | Electrical applications, roofing |

| Aluminum | Moderate | Good | Aerospace, automotive, packaging |

| Steel | Low | Fair | Construction, manufacturing |

| Brass | High | Good | Musical instruments, fittings |

| Titanium | High | Low | Aerospace, medical implants |

| Zinc | Low | Low | Galvanizing, roofing |

| Nickel | Moderate | Fair | Plating, batteries |

| Lead | Low | Poor | Batteries, radiation shielding |

| Bronze | High | Good | Statues, bearings |

| Carbon Steel | Low | Fair | Machinery, tools |

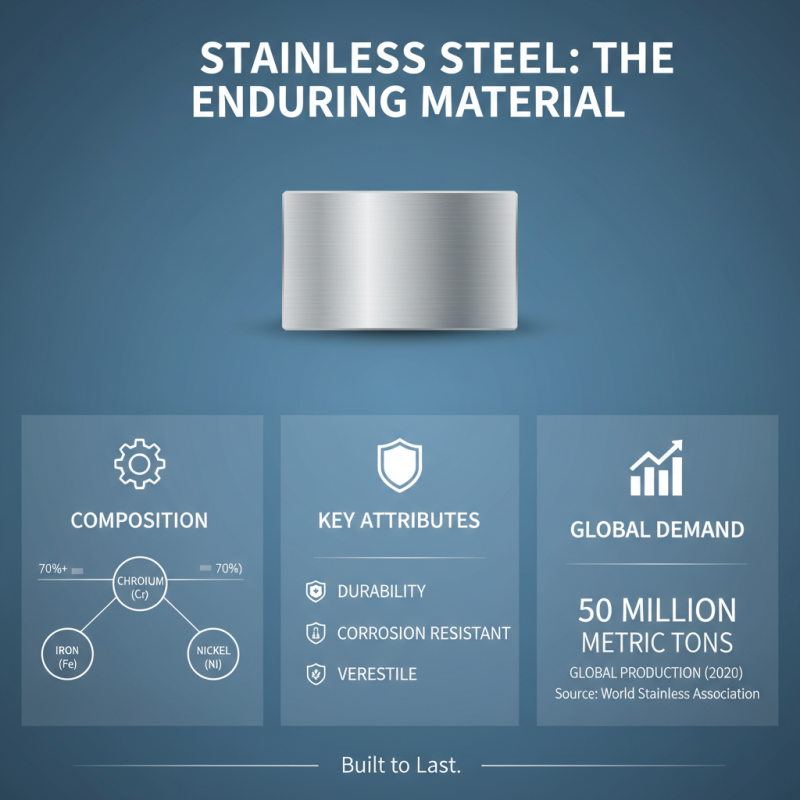

Stainless steel sheets are essential in many projects. Their durability is one of the main reasons for their popularity. Made primarily of iron, chromium, and nickel, they can withstand severe conditions. A report from the World Stainless Association indicates that stainless steel production reached 50 million metric tons in 2020. This growth shows strong demand for resilient materials.

Corrosion resistance is another standout feature. Stainless steel resists rust and staining. This trait makes it ideal for outdoor applications. The high chromium content forms a protective layer. According to a study by the International Stainless Steel Forum, approximately 75% of stainless steel is recycled. This sustainability aspect is crucial in today’s eco-conscious world.

However, there are always challenges. The cost of stainless steel sheets can be higher than carbon steel options. Budget constraints can limit choices for some projects. Additionally, the fabrication process can be more complex. Some users may find working with stainless steel sheets daunting. This requires further training and expertise. Open discussions about these limitations can help improve industry practices.