0102030405

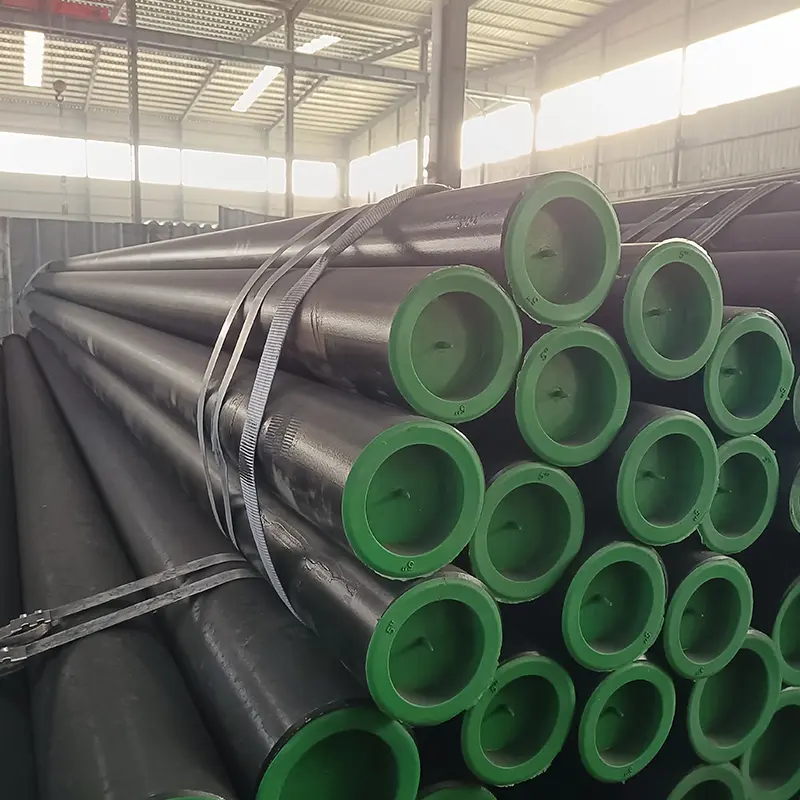

Carbon Steel Pipes Q345B/Q195/Q215

Materials

Carbon steel material: Carbon steel pipes are usually divided into low carbon steel, medium carbon steel and high carbon steel according to the carbon content. Common materials include:

Q195: Low carbon steel, suitable for general purpose.

Q235: Medium carbon steel, widely used in buildings and structures.

Q345: High-strength low-alloy steel, suitable for applications with high load-bearing requirements.

Specifications

Diameter: The outer diameter of carbon steel pipe is usually between 10mm and 1000mm, and the specific diameter can be customized according to requirements.

Wall thickness: The wall thickness is usually between 1mm and 20mm, and the specific thickness can be provided according to customer needs.

Length: Carbon steel pipes are usually provided in cut-to-length or coil form, and the length can be customized according to customer needs.

Production process

Hot Rolling or Cold Rolling Process: Carbon Steel Pipes can be produced by either hot rolling or cold rolling process.

Hot rolling process: suitable for pipes with larger diameter and thickness, with better plasticity and toughness.

Cold rolling process: Suitable for tubes requiring higher precision and surface finish.

Surface treatment

Surface finish: The surface of carbon steel pipes is usually rough, which is suitable for subsequent processing.

Rust-proof treatment: Anti-rust treatment such as oiling or galvanizing can be performed as required to improve corrosion resistance.

Advantages

High Strength: Carbon steel pipes have good strength and toughness, suitable for bearing greater pressure and load.

Affordability: Relatively low cost makes it an affordable choice.

Good processability: Carbon steel pipes are easy to cut, weld and form, suitable for various manufacturing processes.

Application Areas

Construction Industry: For structural support, pipes and framing.

Oil and Gas Industry: Used to transport oil, natural gas and other fluids.

Chemical Industry: used for transportation and storage of chemicals.

Manufacturing Industry: Used in machinery and other industrial applications.

Maintenance

Regular Inspection: It is recommended to regularly inspect the surface of carbon steel pipes to ensure there is no rust and damage.

CLEAN: Keep the surface clean to avoid accumulation of dirt and chemicals.

Product Specifications

| Place of Origin | China |

| Oiled or Non-oiled | Non-oiled |

| Alloy Or Not | Non-Alloy |

| Tolerance | ±1% |

| Special Pipe | Thick Wall Pipe,EMT Pipe |

| Out Diameter | 10-1500mm |

| wall thickness | 0.4-25mm |

| Length | 1-12m |

| Shape | Round, Square or Rectangular |

| Itmes | 4 6 12 inch SCH 40 80 black carbon steel pipe |

| processing service | Bending, Welding, Decoiling, Punching, Cutting |

| Secondary Or Not | Non-secondary |

| technology | hot rolled, cold rolled, black annealed |

| Keyword | welded steel pipe |

| End protector | Plastic Pipe Cap |

| Thickness | 0.35 - 100mm |

| Standard | API, ASTM, bs, GB, API 5L, ASTM A106-2006, ASTM A53-2007, BS 1387, BS 1139, BS EN10219, GB 3087-1999, GB/T3901, EN, BS, JIS |

| Technique | ERW /LSAW/SSAW |

| Surface Treatment | Paint oil; Varnish; Galvanized; Galvanize the raw strip steel; |

| Certificate | Bsi, RoHS, SNI, BIS, SASO, SONCAP, sirm, ISO9001, API, ISO |

Grade

10#, 20#, 45#, Q235, Q345, Q195, Q215, ST52, ST42, ST35, 10#-45#, Q195-Q345, ST35-ST52

Q235, Q235B, S275, S275jr, A53, st37, st52

Q195 → Grade B, SS330,SPHC, S185

Q215 → Grade C,CS Type B,SS330, SPHC

Q235 → Grade D,SS400,S235JR,S235JO,S235J2

Q345 → SS500,ST52

Application

Usage:

Mechanical manufacture, construction field, metallurgy industry, farm vehicles, agriculture greenhouse, automotive industry, railway, highway guardrail, container frame, furniture, decoration, steel structure, Chemical Fertilizer Pipe, Structure Pipe, Building Construction

Package

Standard Seaworthy Packing

tied with steel trips,then wrapped by plastic material or as request

transport

010203040506070809