0102030405

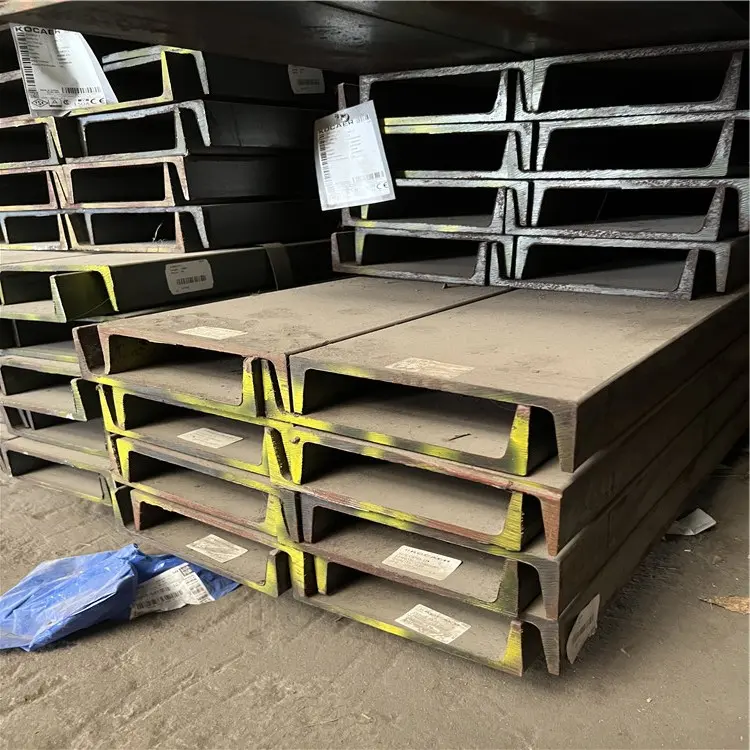

Channel Steel (C-channel steel, U-channel steel)

Product Description

1. Strong bending load-bearing capacity: The cross-sectional shape of channel steel determines its high bending stiffness and load-bearing capacity, which can effectively withstand external loads and maintain structural stability.

2. Simple manufacturing process: The manufacturing process of channel steel is relatively simple and can be formed by hot rolling or cold bending, which not only reduces manufacturing costs, but also improves production efficiency.

Product Details

Channel Steel is a steel material with a U-shaped cross section, which is widely used in the fields of construction, machinery manufacturing, bridges, vehicles, etc. The following is the detailed product information about channel steel:

Materials

Steel material: Channel steel is usually made of carbon structural steel (such as Q235, Q345, etc.) or alloy steel. The specific material can be selected according to project requirements.

Specifications

Sectional size: The cross-sectional size of the channel steel is usually expressed in height (h) and wing width (b). Common specifications include:

Height: from 50mm to 400mm.

Wing width: varies from 30mm to 200mm.

Wall thickness: The wall thickness of channel steel is usually between 5mm and 20mm, and the specific thickness can be customized according to requirements.

Length: The standard length is generally 6 meters, special lengths can be customized according to customer needs.

Production process

Hot rolling process: Channel steel is usually produced by hot rolling process to ensure its strength and toughness.

Surface treatment

Surface finish: The surface of the channel steel can be treated with anti-rust treatment, such as hot-dip galvanizing, spraying, etc. to improve corrosion resistance.

Coating: Some channels may be given a protective coating to enhance corrosion resistance.

Advantages

High Strength: Channel steel has good load-bearing capacity and is suitable for structural support.

Processability: Channel steel is easy to cut, weld and form, suitable for various manufacturing processes.

Stability: The U-shaped cross-section design gives it good stability when subjected to stress.

Application Areas

Construction industry: used for building frames, supporting structures and stairs, etc.

Mechanical Manufacturing: used for supports and frames of mechanical equipment.

Bridge Engineering: Used for structural support of bridges.

Vehicle Manufacturing: Chassis and frames for cars, trucks, etc.

Maintenance

Regular inspection: It is recommended to regularly inspect the surface of the channel steel to ensure it is free of rust and damage.

CLEAN: Keep the surface clean to avoid accumulation of dirt and chemicals.

Product Specifications

| Product Name | Channel Steel |

| Place of Origin | Hebei, China |

| Standard | GB,GB/T,JIS,DIN,ASTM |

| Shape | U/C Channel |

| Perforated | Or Not Customized |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Punching, Cutting |

| Grade | Q235/Q345/A36/SS400/ST52/Q195/Q460/S235JR/S275JR/St37-2 |

| Dimensions | 50*37*4.5mm~400*104*14.5mm |

| Technique | Hot Rolled / Cold Bending |

Payment terms

MOQ:One ton or according to customer demand

Usage:Industry, Construction, Etc..

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

transport

010203040506070809