01

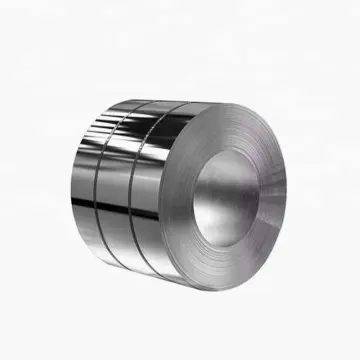

Cold Rolled Stainless Steel Coil

Characteristics of stainless steel

1. Complete product specifications and diverse materials;

2. High dimensional accuracy, up to ±0.1mm;

3. Excellent surface quality and good brightness;

4. Strong corrosion resistance, tensile strength and fatigue resistance High strength;

5. Stable chemical composition, pure steel, low inclusion content;

6. Well packaged, favorable price;

7. Non-standard customization is available.

Materials

Stainless steel material: Cold rolled stainless steel coils usually use different types of stainless steel materials such as 304, 316, 430, etc.

304 stainless steel: has good corrosion resistance and formability, suitable for general environment.

316 stainless steel: Contains molybdenum, has stronger corrosion resistance and is suitable for marine and chemical environments.

430 stainless steel: has good corrosion resistance and is suitable for low and medium temperature environments.

Specifications

Thickness: The thickness of cold rolled stainless steel coils is usually between 0.1mm and 3.0mm, and the specific thickness can be customized according to requirements.

Width: Common widths range from 1000mm to 1500mm, which can be provided according to customer needs.

Length: Cold rolled stainless steel coils are usually supplied in coil form and the length can be customized according to customer needs.

Production process

Cold Rolling Process: Cold rolled stainless steel coils are made by further processing hot rolled stainless steel at room temperature, increasing the strength and hardness of the material while improving the surface finish.

Surface treatment

Surface Finish: The surface of cold rolled stainless steel coils is usually smooth with good gloss, suitable for decorative applications.

Surface treatment: Different surface treatments can be provided according to requirements, such as pickling, polishing, brushing, etc.

Advantages

Excellent surface quality: The cold rolling process gives the stainless steel coil a smooth surface, suitable for demanding applications.

High Strength: The cold rolling process increases the strength of the material, making it suitable for withstanding greater pressure and loads.

Corrosion resistance: Stainless steel material has excellent corrosion resistance and is suitable for use in harsh environments.

Application Areas

Construction industry: used for building decoration, curtain walls, railings, etc.

Home appliance industry: used for housings of refrigerators, washing machines, kitchen equipment, etc.

Automotive industry: used for automotive parts and decorative components.

Manufacturing Industry: Used in machinery and other industrial applications.

Maintenance

Regular Inspection: It is recommended to regularly inspect the surface of cold rolled stainless steel coils to ensure there is no oxidation and corrosion.

CLEAN: Keep the surface clean to avoid accumulation of dirt and chemicals.

Product Specifications

| Application | Building, Construction, Deaoration |

| Thickness | 1.5-15mm 0.3-3.0mm |

| Standard | GB |

| Width | 1000 1220 1500 1800 2000mm |

| Certificate | ISO9001 |

| Grade | 200 Series, 300 Series, 400 Series |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Steel Grade | 301L, 301, 310S, 410, 316L, 316, 314, 430, 304, 304L, 305 |

| Surface Finish | TSHS |

| Delivery Time | 15-21 days |

| Product name | Stainless Steel Coil |

| Technique | Cold Rolled |

| Thickness | 0.3-3.0mm/1.5-15mm |

| Width | 1000-2000mm |

| Material | 200 Series/300 Series/400series/copper |

| Level | 2B 8K BA HL |

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

transport

010203040506070809