0102030405

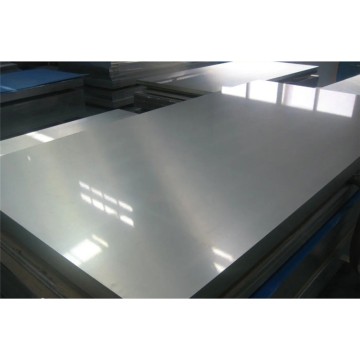

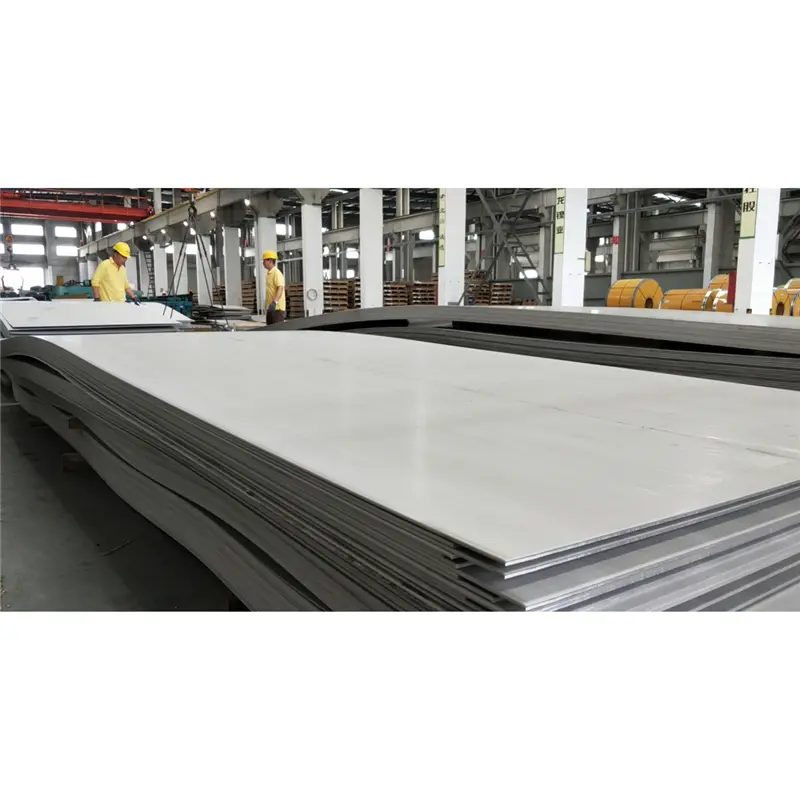

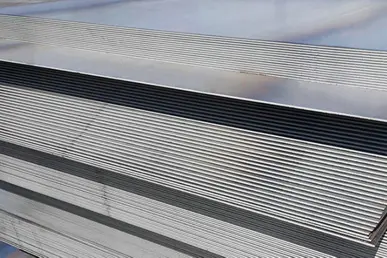

Cold Rolled Stainless Steel Sheet

Product Description

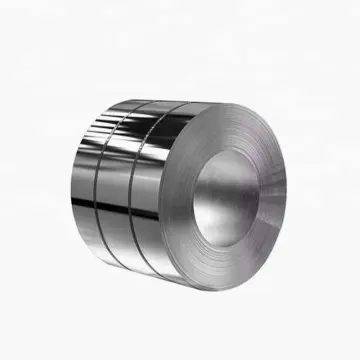

Cold rolled sheet is a product made by rolling hot-rolled coils at room temperature below the recrystallization temperature. Mostly used in automobile manufacturing, electrical products, etc. Cold rolling is rolling at recrystallization temperature, but generally understood as rolling materials using room temperature rolling.

Materials

Stainless steel material: Common cold-rolled stainless steel plate materials include 304, 316, 430, etc.

304 stainless steel: widely used, with good corrosion resistance and formability.

316 stainless steel: Contains molybdenum, more corrosion-resistant, suitable for marine and chemical environments.

430 stainless steel: has good corrosion resistance and is suitable for low and medium temperature environments.

Specifications

Thickness: The thickness of cold rolled stainless steel plates is usually between 0.3mm and 6mm, and the specific thickness can be customized according to requirements.

Width: Common widths are 1000mm, 1219mm, 1500mm, etc., which can be provided according to customer needs.

Length: Standard lengths are generally 2000mm, 2438mm, 3000mm, etc. Special lengths can be customized.

Production process

Cold Rolling Process: By further processing the hot rolled stainless steel sheets at room temperature, the cold rolling process can increase the strength and hardness of the material while improving the surface finish.

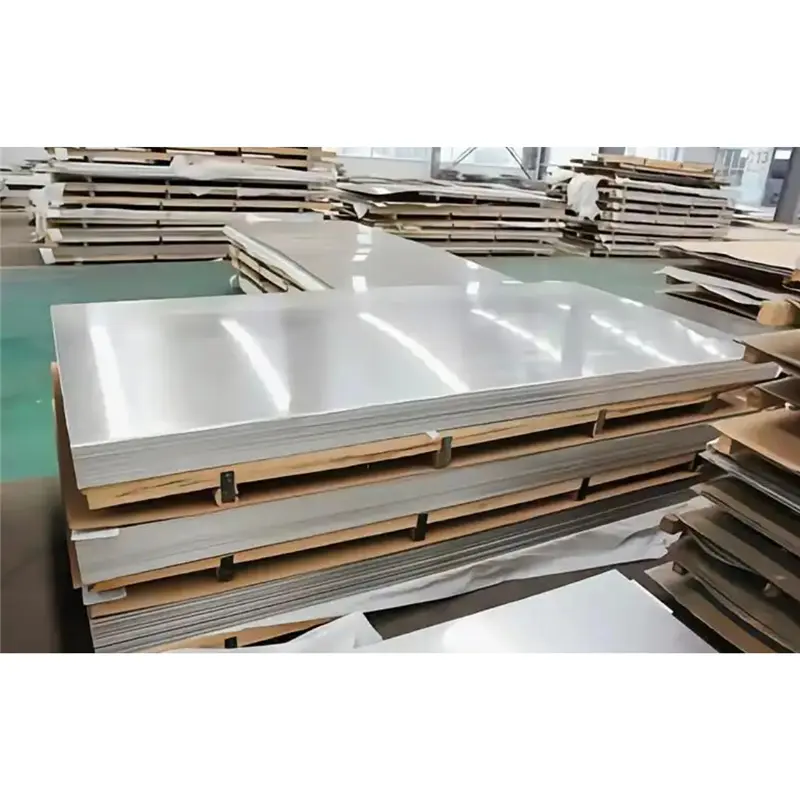

Surface treatment

Surface finish: Cold rolled stainless steel sheets usually have a higher surface finish, common surface treatments include:

2B: Smooth surface, suitable for most applications.

BA: mirror polished with higher gloss.

NO.4: Brushed surface, suitable for decorative purposes.

Advantages

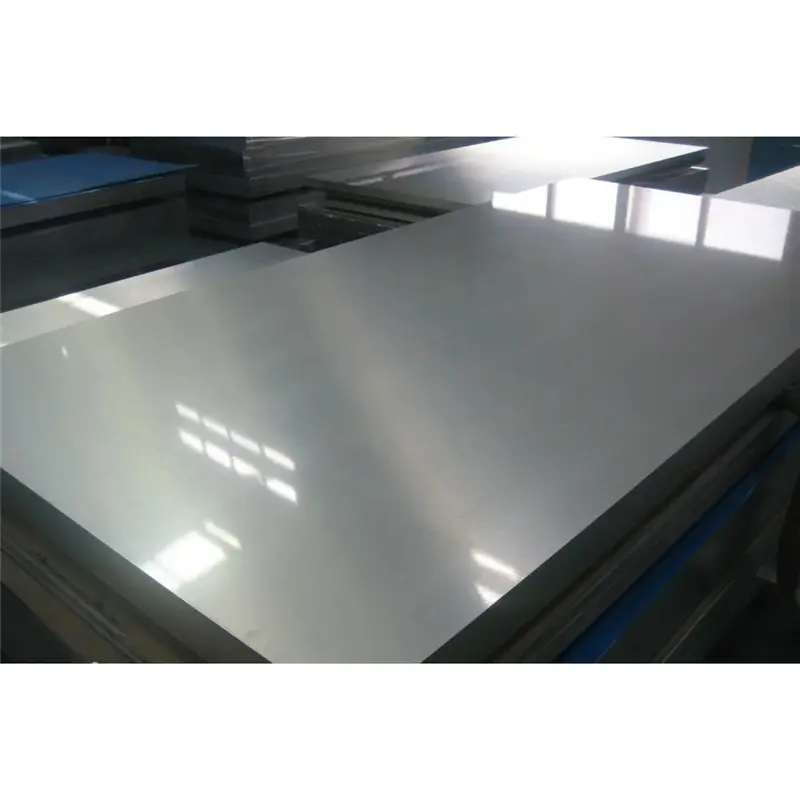

Excellent mechanical properties: Cold rolled stainless steel plates have high strength and hardness, suitable for bearing greater pressure and load.

Good Corrosion Resistance: The properties of stainless steel material make it perform well in a variety of environments.

Aesthetics: The high gloss finish makes it very popular in decorative applications.

Application Areas

Construction industry: used for exterior wall decoration, roofs, railings, etc.

Home appliance industry: used for the outer shells of refrigerators, washing machines and other home appliances.

Food and pharmaceutical industries: For use in equipment and pipelines with high hygiene requirements.

Automotive industry: used for automotive parts and decorative components.

Maintenance

Regular Cleaning: Keep the surface clean to avoid the accumulation of dirt and chemicals.

Rust-proof treatment: When used in a humid environment, check and perform rust-proof treatment regularly.

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

transport

010203040506070809