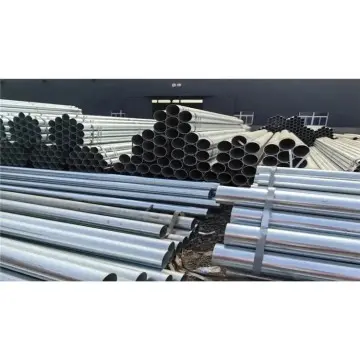

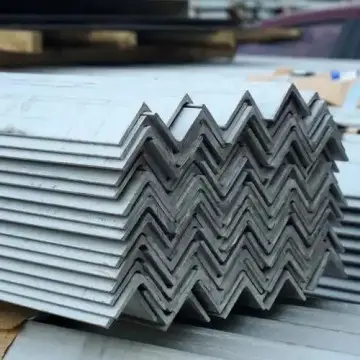

Buy Quality Color Coated & Hot Dip Galvanized Steel Coils from Trusted Suppliers

At Hebei Hegang Supply Chain Co., Ltd., we offer premium Color Coated Steel Coils and Hot Dip Galvanized Steel Coils tailored to meet the requirements of various industries. Our color coated steel coils come in an array of finishes and colors, ideal for diverse projects. The hot dip galvanized steel coils provide outstanding corrosion resistance, guaranteeing exceptional durability and longevity for your applications. Count on us for high-quality products that enhance your manufacturing processes.Best Practices For Color Coated Steel Coil And Hot Dip Galvanized Steel Coil Sets the Industry Standard Industry Leaders

In today's competitive manufacturing landscape, the choice of materials significantly influences product performance and durability. Color coated steel coils and hot dip galvanized steel coils are rapidly becoming industry standards, offering exceptional resistance to corrosion and aesthetic appeal. These materials not only enhance the lifespan of products but also provide manufacturers with versatility for various applications, ranging from construction to automotive. By implementing best practices in the selection and use of these materials, businesses can achieve superior quality while reducing maintenance costs and improving customer satisfaction. Industry leaders are increasingly recognizing the advantages of integrating advanced processes and technologies when working with these steel coils. Innovations in coating techniques and galvanization processes have led to improved adhesion, better surface finishes, and enhanced protective properties. Furthermore, suppliers who specialize in these materials are now able to offer customized solutions tailored to the specific needs of diverse sectors including petrochemicals, aerospace, and mechanical engineering. Such partnerships not only elevate product offerings but also streamline operations, ensuring that clients receive high-quality components that meet stringent industry standards. As the demand for sustainable and durable materials continues to grow, procurement strategies that focus on color coated and hot dip galvanized steel coils will lead to significant competitive advantages. By prioritizing these advanced materials, global buyers can not only enhance the quality of their products but also align with contemporary environmental considerations. Embracing these best practices positions companies at the forefront of innovation, enabling them to respond proactively to market demands while fostering long-term relationships with suppliers dedicated to excellence.

Best Practices For Color Coated Steel Coil And Hot Dip Galvanized Steel Coil Sets the Industry Standard Industry Leaders

| Dimension | Color Coated Steel Coil | Hot Dip Galvanized Steel Coil | Best Practice |

|---|---|---|---|

| Thickness (mm) | 0.20 - 2.5 | 0.25 - 6.0 | Use appropriate thickness based on application |

| Width (mm) | 600 - 1500 | 600 - 1500 | Standard width for compatibility |

| Coating Weight (g/m²) | 15 - 25 | 60 - 140 | Ensure proper coating for corrosion protection |

| Surface Treatment | Polyester, PVDF | Passivation, Chromate | Choose treatment suitable for environment |

| Applications | Roofing, Siding | Automotive, Construction | Select based on application needs |

Comprehensive Comparison of Color Coated Steel Coil And Hot Dip Galvanized Steel Coil Outperforms the Competition Where Innovation Meets 2025

S

Samuel Wright

The after-sales team was extremely professional and made sure I was happy with my purchase.

28 June 2025

V

Victoria Price

This product is worth its price! I appreciate the quality and excellent service.

22 June 2025

E

Evelyn Cooper

This product has exceeded my expectations in terms of quality. Kudos to the support team!

11 May 2025

A

Audrey Hughes

Superb quality! The customer service experience has been outstanding.

01 June 2025

A

Anthony Reed

The quality is outstanding! The professionalism of the customer service staff is commendable.

15 May 2025

M

Maya Collins

Outstanding service! The quality of the product is fantastic, too.

12 June 2025