0102030405

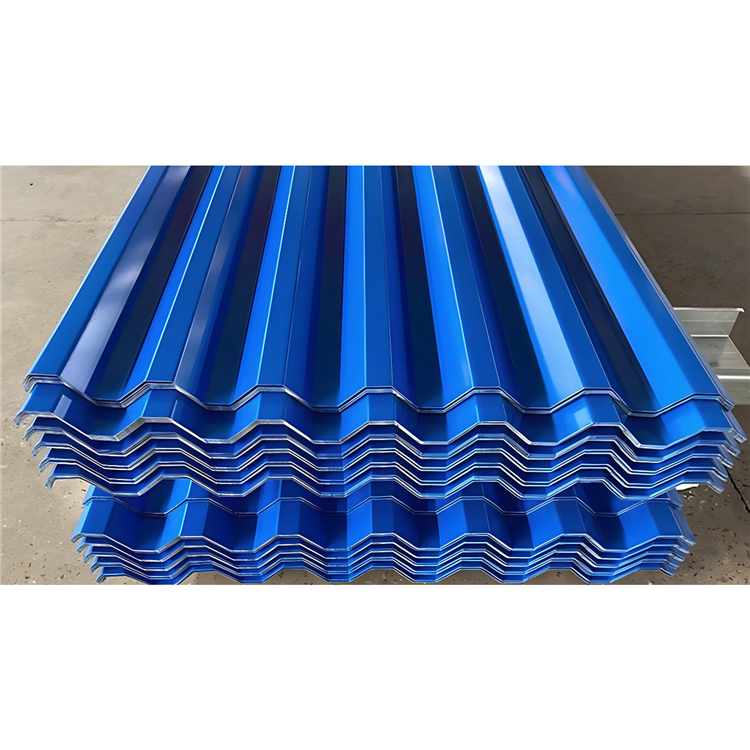

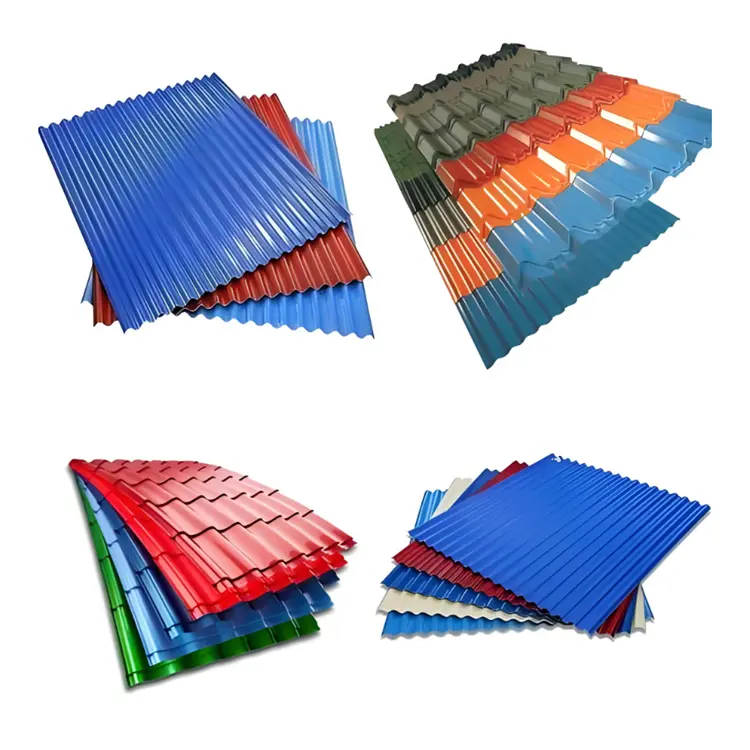

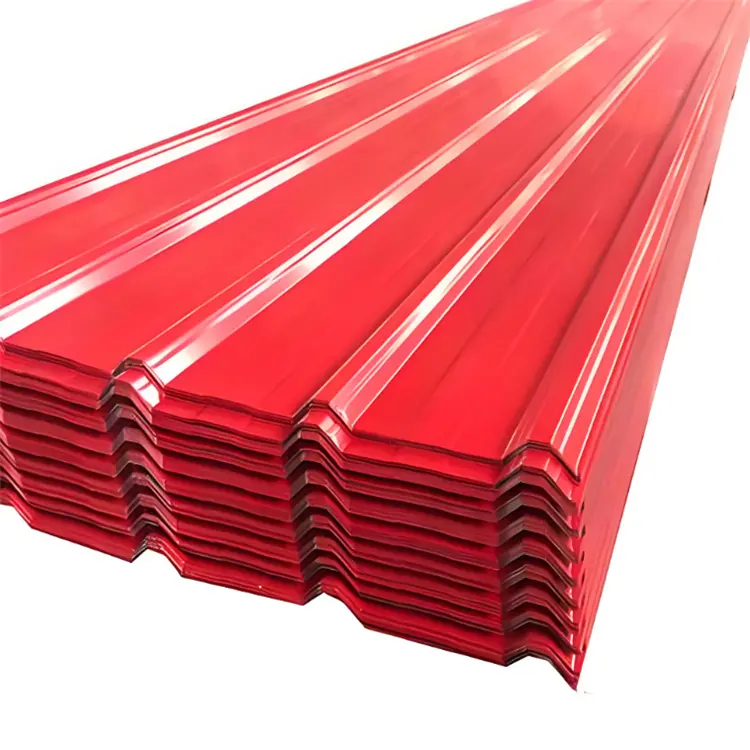

GI Roofing Sheet Corrugated Roofing Sheet Metal

Product Specifications

| Standard | AiSi, ASTM, bs, GB, JIS |

| Grade | Dx51D/Dx52D/Dx53D/Dx53D/S250GD/S350GD/S550GB |

| Model Number | Customized |

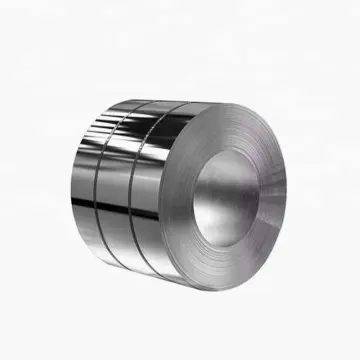

| Type | Steel Coil, Color Coated Steel Sheet |

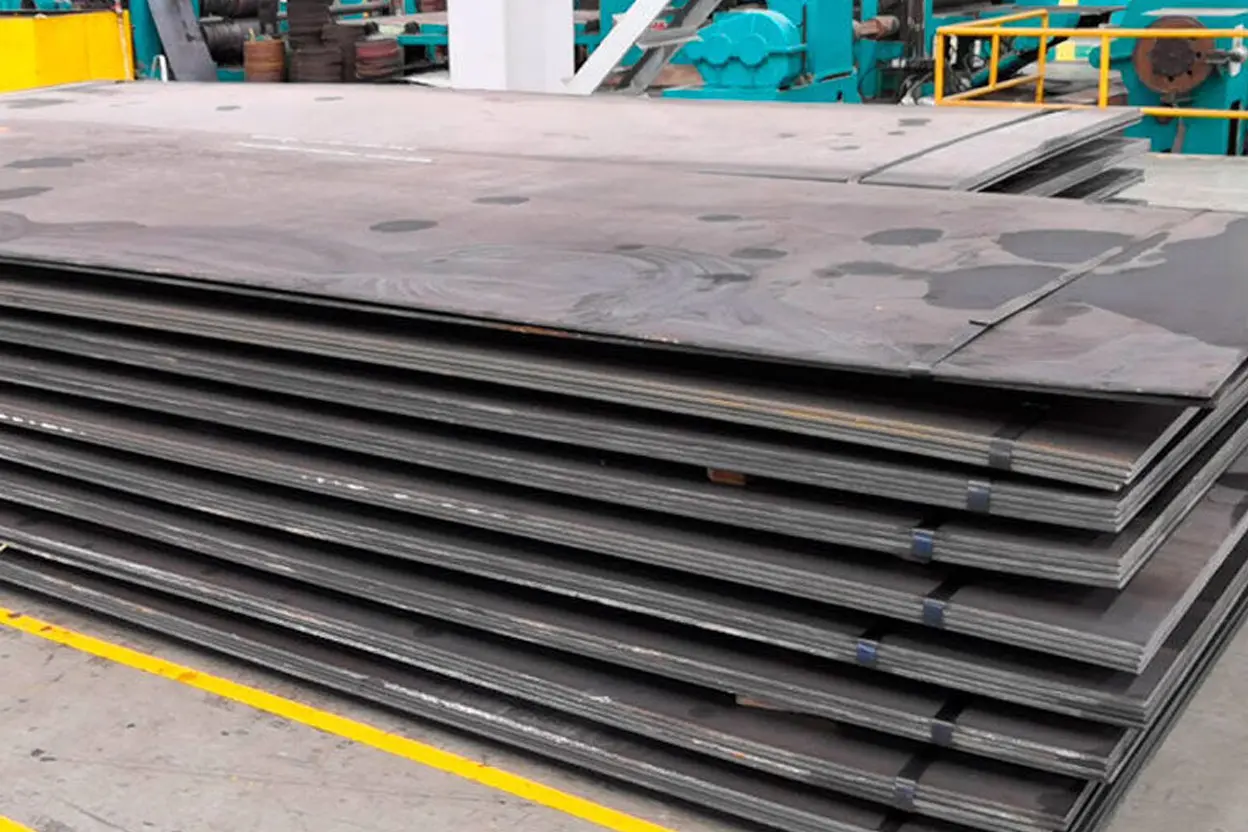

| Technique | Cold Rolled |

| Surface Treatment | galvanized |

| Application | Building |

| Special Use | High-strength Steel Plate |

| Width | 600mm--1500mm |

| Length | Customer's Requirement |

| Tolerance | ±1% |

| Width | 600mm-1500mm, according to customer requirements |

| Thickness | 0.12-6.00mm |

| Galvanized weight | 20g/m2--275g/m2 |

| Standard | AiSi, ASTM, bs, GB, JIS |

| Steel type | Dx51D/Dx52D/Dx53D/Dx53D/S250GD/S350GD/S550GB |

| Applications | home appliances, building materials, machinery, roof panels, etc. |

| Quality | Certified by SGS |

| Certification | ISO9001 |

| Packing | Waterproof paper is the inner packing, galvanized steel or coated steel is the outer packing, side guards, and then wrapped with seven steel strips. |

Materials

Galvanized Steel Sheet: Galvanized corrugated roofing sheets are made of galvanized steel sheets, which are coated with a layer of zinc to prevent corrosion and rust.

Specifications

Thickness: Common thickness range is 0.3mm to 1.0mm, and the specific thickness can be selected according to needs.

Width: Standard width is usually 1000mm (1 meter) or 1200mm (1.2 meters).

Length: Can be customized according to project requirements, common length range is 2000mm to 6000mm.

Ripple Design

Corrugation height: Generally between 18mm and 30mm, the specific height can be adjusted according to design requirements.

Corrugation spacing: Usually 75mm to 150mm, the corrugated design enhances the strength and rigidity of the board.

Surface treatment

Coating: The surface of the galvanized corrugated roof sheet can be treated with coatings, such as polyester coating or fluorocarbon coating, to improve weather resistance and aesthetics.

Surface treatment

Coating: The surface of the galvanized corrugated roof sheet can be treated with coatings, such as polyester coating or fluorocarbon coating, to improve weather resistance and aesthetics.

Color: A variety of colors are available to meet the needs of different architectural styles.

Advantages

Durability: The zinc coating provides good protection against rust and is suitable for all climate conditions.

Lightweight: Compared with traditional roofing materials, galvanized corrugated roofing sheets are lighter and easier to transport and install.

Affordability: Relatively low cost makes it an affordable choice.

Easy to install: The corrugated design makes the installation process simple and quick, reducing construction time and cost.

Application

Residential buildings: Suitable for family homes, villas, etc.

Commercial Buildings: Widely used in commercial buildings such as warehouses, factories, shops, etc.

Agricultural buildings: commonly used in farms, greenhouses, livestock sheds, etc.

Maintenance

Regular Inspection: It is recommended to inspect the roof regularly to clear debris and ensure smooth drainage.

Rust-proofing: While the zinc coating provides protection against rust, in extreme environments additional rust-proofing may be required.

FACTORY PICTURES

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

transport

010203040506070809