01

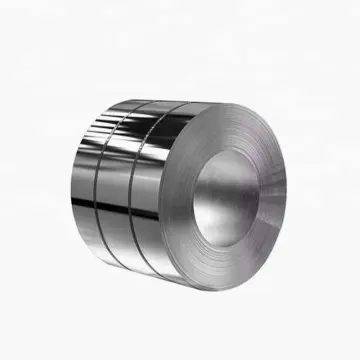

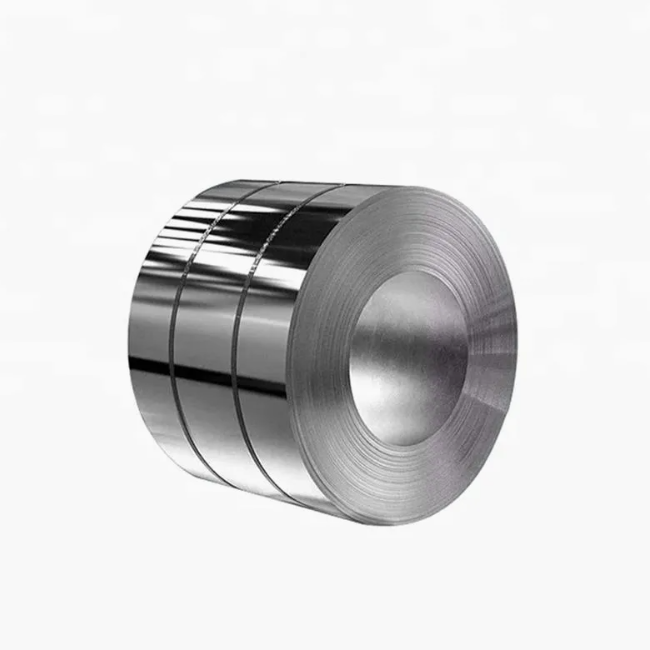

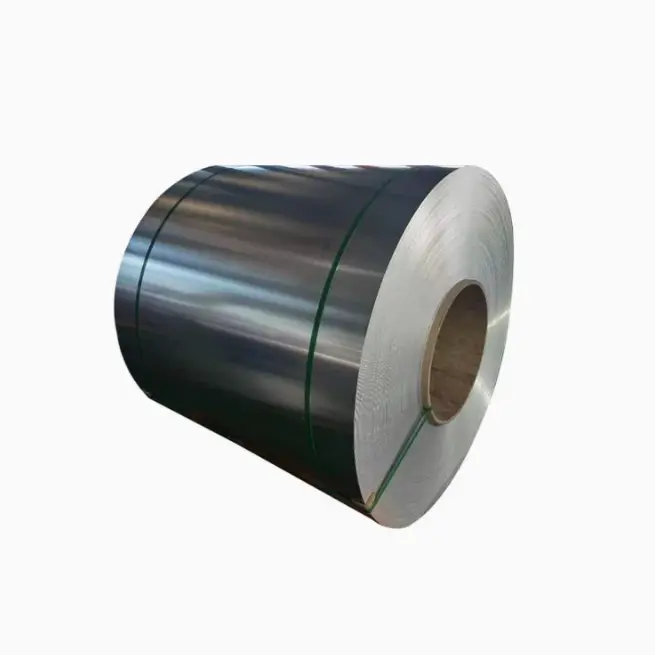

Hot Rolled Stainless Steel Coil

Product Description

Material Grade: 201/304/304l/316/316l/321/309s/310s/410/420/430/904l/2205/2507

Type: Ferritic, Austenite, Martensite, Duplex

Technology: Cold Rolled and Hot Rolled

Size: According to the customer's requests

Standards: AISI ASTM JIS SUS DIN EN and GB

Certifications: ISO 9001, SGS, BV

Materials

Stainless steel material: Hot rolled stainless steel coils usually use different types of stainless steel materials such as 304, 316, 321, etc.

304 stainless steel: has good corrosion resistance and formability, suitable for general environment.

316 stainless steel: Contains molybdenum, has stronger corrosion resistance and is suitable for marine and chemical environments.

321 stainless steel: With the addition of titanium, it has good high temperature resistance and is suitable for high temperature environments.

Specifications

Thickness: The thickness of hot rolled stainless steel coils is usually between 1.5mm and 25mm, and the specific thickness can be customized according to requirements.

Width: Common widths range from 1000mm to 2000mm, which can be provided according to customer needs.

Length: Hot rolled stainless steel coils are usually supplied in coil form and the length can be customized according to customer needs.

Production process

Hot rolling process: Hot rolled stainless steel coil reduces the hardness of the material and improves the plasticity and toughness by rolling the stainless steel billet at high temperature.

Surface treatment

Surface finish: The surface of hot rolled stainless steel coils is usually rough, which is suitable for subsequent processing.

Surface treatment: Different surface treatments can be provided according to requirements, such as pickling, polishing, etc.

Advantages

High Strength: The hot rolling process gives the stainless steel coils higher strength and toughness, making them suitable for withstanding greater pressure and load.

Good Processability: Hot rolled stainless steel coils are easy to cut, weld and form, suitable for various manufacturing processes.

Corrosion resistance: Stainless steel material has excellent corrosion resistance and is suitable for use in harsh environments.

Application Areas

Construction Industry: used for structural support, frames, railings, etc.

Manufacturing Industry: For use in machinery, equipment, tools and other industrial applications.

Automotive industry: used in automotive chassis and body parts.

Chemical Industry: Used in equipment and pipelines, especially in corrosive environments.

Maintenance

Regular Inspection: It is recommended to inspect the surface of the hot rolled stainless steel coil regularly to ensure there is no oxidation and corrosion.

CLEAN: Keep the surface clean to avoid accumulation of dirt and chemicals.

Product Specifications

| Product Name | Hot/Cold Rolled ASTM SUS JIS 201/304/316/321/316L |

| Thickness | 0.1-20 mm |

| Package | Seaworthy Wooden Pallets and Waterproof Paper |

| Key Word | Stainless Steel Coil |

| Specification | 0.1mm-16mm |

| Production Capacity | 1000000/Year |

| Tolerance | ±1% |

| Shape | Flat Plates, Coils, and Plates |

| Processing Services | Welding, Punching, Cutting, Bending, Uncoiling |

| Width | 10mm-2000mm |

| Grade | 201, 202, 304, 304l, 316, 316l, 309, 310s, 321, 409, 409l, 410, 420, 430, etc |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Container size |

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

Grade and Main chemical composition%

| C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | other | |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | 0.06 | 0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10.0 | 0.06 | 0.03 | 17-19 | - | 4.0-6.0 | N≤0.25 |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | - | 6.0-8.0 | - |

| 303 | ≤0.15 | ≤1.00 | ≤2.00 | 0.2 | ≥0.015 | 17-19 | ≤0.6 | 8.0-10.0 | - |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 8-10.5 | - |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 3 February | 14th October | - |

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | 0.04 | 0.03 | 16-18 | - | ≤0.6 | - |

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

transport

010203040506070809