Is Carbon Steel Better Than Steel

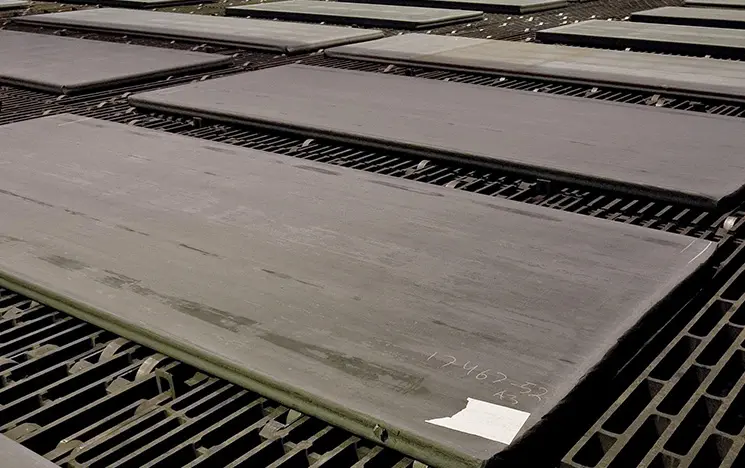

In the industrial field, carbon steel and ordinary steel are two common types of steel, each with its unique properties and applicable scenarios. The carbon content of carbon steel ranges from 0.12% to 2.0%, and its hardness increases with the increase of carbon content, exhibiting excellent wear resistance and fatigue resistance. Therefore, it is commonly used to manufacture mechanical parts such as cutting tools, springs, and bearings. Carbon Steel Plate is an iron carbon alloy with a carbon content between 0.0218% and 2.11%, also known as carbon steel. It usually contains small amounts of elements such as silicon, manganese, sulfur, and phosphorus. Depending on the carbon content, carbon steel plates can be divided into low carbon steel, medium carbon steel, and high carbon steel. Low carbon steel has a carbon content generally less than 0.25%, good plasticity, and weldability, and is widely used in automobile manufacturing and building structures. Medium carbon steel: with a carbon content between 0.25% and 0.60%, it has high strength and hardness and is suitable for parts in mechanical manufacturing; High carbon steel: with a carbon content greater than 0.60%, it has high hardness and toughness, and is suitable for fields such as cutting tools and springs. Common specifications and uses: The thickness of carbon steel plate is usually between 0.5mm and 300mm. Thin carbon steel plates (0.5mm to 4mm) are commonly used in electronic products and automotive components; Medium thick carbon steel plate (4mm to 20mm) is suitable for construction and machinery manufacturing; Thick carbon steel plates (over 20mm) are used for the manufacturing of large machinery and ships. The width of carbon steel plate is generally between 1000mm and 3000mm, and the length is usually between 2000mm and 12000mm. Different specifications of plates can be customized according to needs. Common brand names Common carbon steel plate grades include Q195, Q235A, Q235B, Q235C, Q235D, Q255, and Q275. These grades of carbon steel plates have a wide range of applications in industrial production and construction fields. Relatively speaking, the carbon content of ordinary steel is less than 0.12%. Although its mechanical performance is slightly inferior, it has good processing and welding performance and is widely used in industries such as construction, furniture, and automobile manufacturing. When comparing the durability of the two, carbon steel usually has a longer service life and better durability due to its higher hardness and wear resistance. However, the cost of carbon steel is relatively high, and high carbon content may lead to increased brittleness. Therefore, when selecting materials, it is necessary to weigh them according to actual needs. For fields that require high strength and excellent wear resistance, such as component manufacturing, mold development, and specific recording equipment manufacturing, carbon steel is undoubtedly a better choice. In the fields of general home product manufacturing and low demand building structures, ordinary steel has become a more suitable choice due to its cost-effectiveness and processing convenience. In summary, carbon steel and ordinary steel each have their own advantages. When choosing, the specific requirements of the application scenario should be fully considered to ensure that the material properties match the actual application.