0102030405

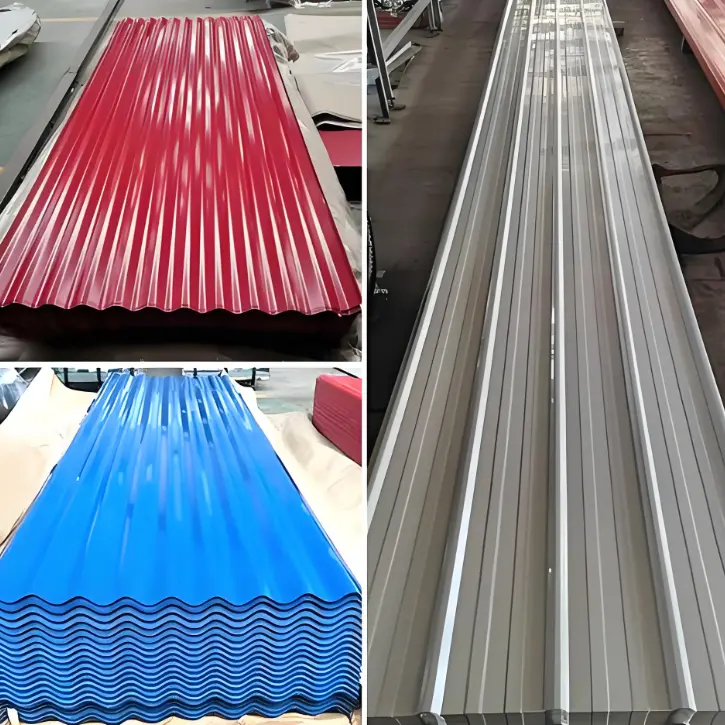

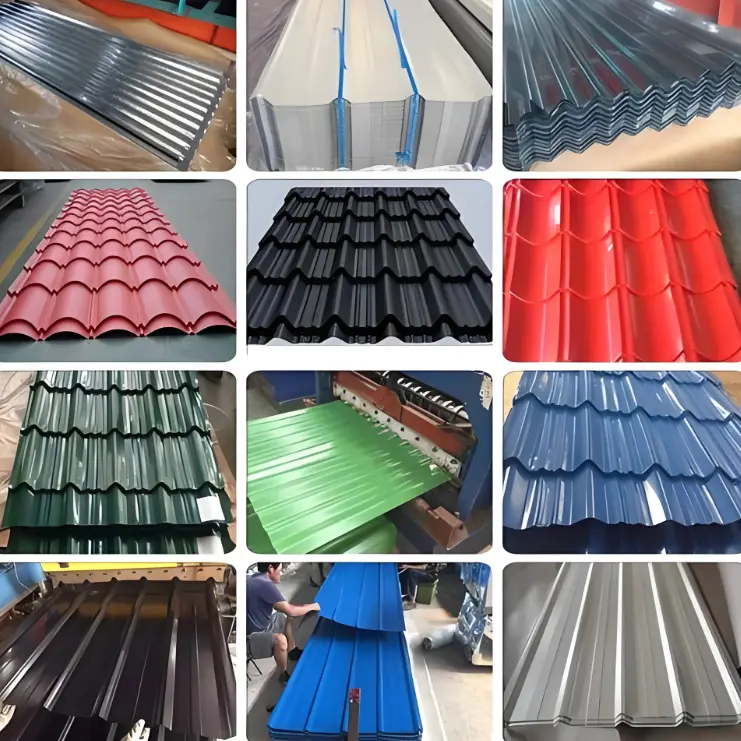

Specifications of PPGI roof panels (0.3mm-1.0mm) and color options

Product Specifications

| Standard | AiSi, ASTM, bs, GB, JIS |

| Grade | Dx51D/Dx52D/Dx53D/Dx53D/S250GD/S350GD/S550GB |

| Model Number | Customized |

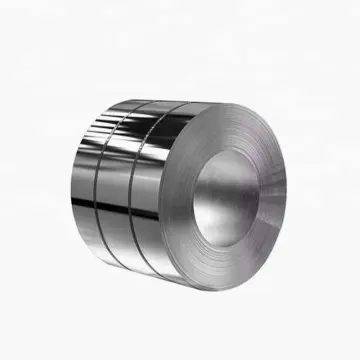

| Type | Steel Coil, Color Coated Steel Sheet |

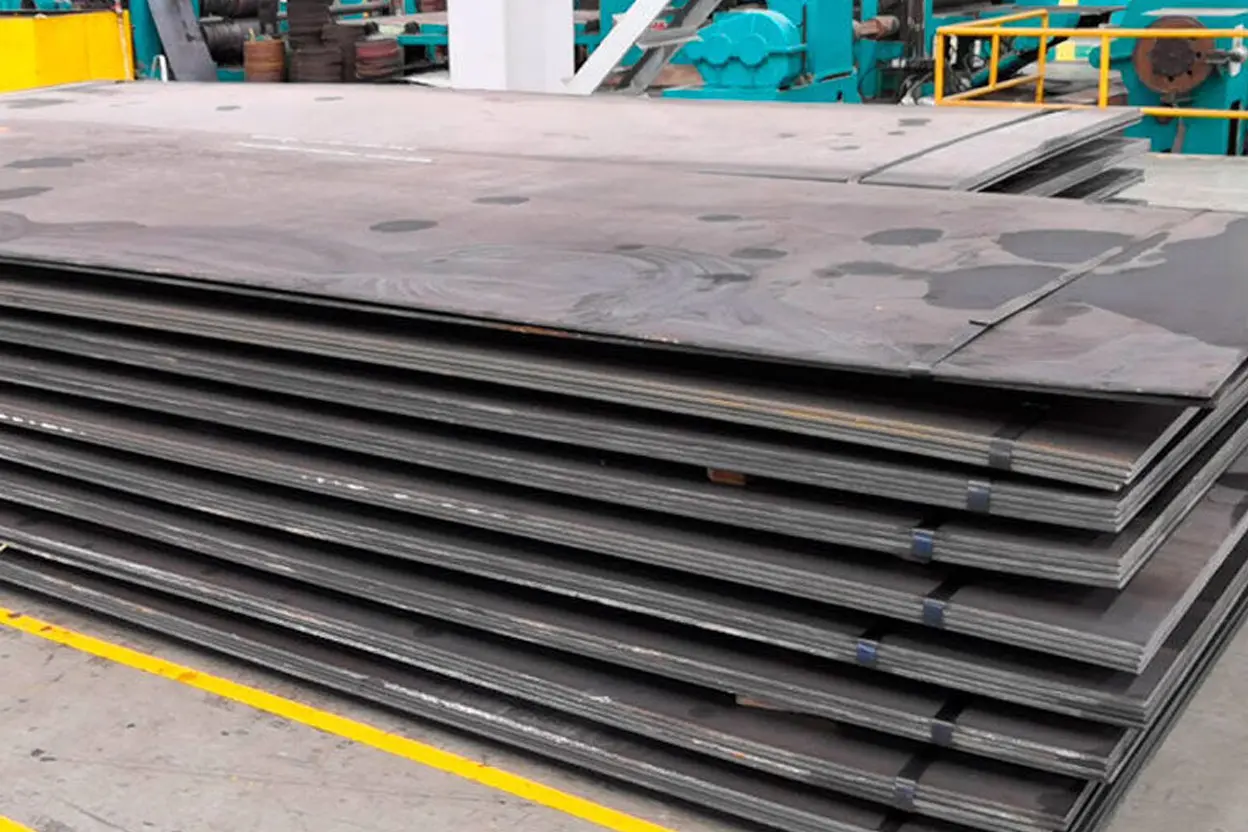

| Technique | Cold Rolled |

| Surface Treatment | galvanized |

| Application | Building |

| Special Use | High-strength Steel Plate |

| Width | 600mm--1500mm |

| Length | Customer's Requirement |

| Tolerance | ±1% |

| Width | 600mm-1500mm, according to customer requirements |

| Thickness | 0.12-6.00mm |

| Galvanized weight | 20g/m2--275g/m2 |

| Standard | AiSi, ASTM, bs, GB, JIS |

| Steel type | Dx51D/Dx52D/Dx53D/Dx53D/S250GD/S350GD/S550GB |

| Applications | home appliances, building materials, machinery, roof panels, etc. |

| Quality | Certified by SGS |

| Certification | ISO9001 |

| Market | North America, Europe, Asia, Africa, Middle East, etc. |

| Packing | Waterproof paper is the inner packing, galvanized steel or coated steel is the outer packing, side guards, and then wrapped with seven steel strips. |

Materials

Substrate: PPGI roof panels usually use galvanized steel sheets as substrate, providing good anti-corrosion performance.

Coating: The coating is generally polyester (PE), fluorocarbon (PVDF) or acrylic, etc., with excellent weather resistance and adhesion.

Specifications

Thickness: The thickness of PPGI roof panels is usually between 0.3mm and 1.5mm, and the specific thickness can be customized according to requirements.

Width: Common widths are 1000mm, 1200mm, 1250mm, etc., which can be provided according to customer needs.

Length: Standard length is generally 2000mm, 3000mm, etc. Special length can be customized.

Surface treatment

Surface Finish: The surface of PPGI roofing sheets is usually smooth, with even coating and bright colors.

Color Selection: A variety of color options are available to meet the needs of different architectural and decorative styles.

Advantages

Corrosion resistance: The zinc coating and coating together provide good corrosion protection and extend the service life.

Aesthetics: A wide range of colors and gloss levels make it very popular in decorative applications.

Lightweight and high strength: PPGI roof panels are relatively light, easy to transport and install, while having good strength.

Application Areas

Construction industry: used for roofs, walls, carports, warehouses and other building materials.

Home appliance industry: used for decoration of home appliance casings.

Industrial Facilities: Used for roofs and walls of industrial plants.

Maintenance

Regular Inspection: It is recommended to regularly inspect the surface of the roof panels to ensure there is no peeling and damage.

CLEAN: Keep the surface clean to avoid accumulation of dirt and chemicals.

factory pictures

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

transport

010203040506070809