01

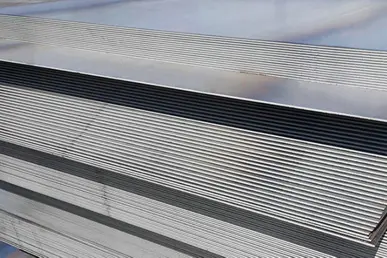

Stainless Steel Bar/Rod 304/316L/904/316

Product Details

Stainless Steel Bar/Rod is a common metal material, widely used in construction, manufacturing, machinery and automobile industries. The following is detailed product information about stainless steel bars:

Materials

Stainless steel material: Stainless steel bars are usually made of different types of stainless steel materials such as 304, 316, 321, etc.

304 stainless steel: has good corrosion resistance and formability, suitable for general environment.

316 stainless steel: Contains molybdenum, has stronger corrosion resistance and is suitable for marine and chemical environments.

321 stainless steel: With the addition of titanium, it has good high temperature resistance and is suitable for high temperature environments.

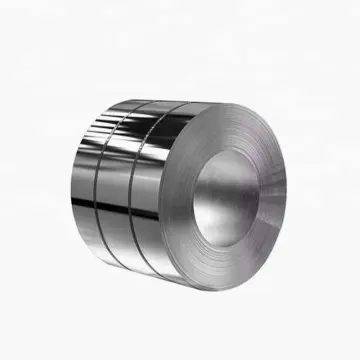

Specifications

Diameter: The diameter of stainless steel bars usually ranges from 3mm to 300mm, which can be customized according to requirements.

Length: The standard length is generally 6 meters, special lengths can be customized according to customer needs.

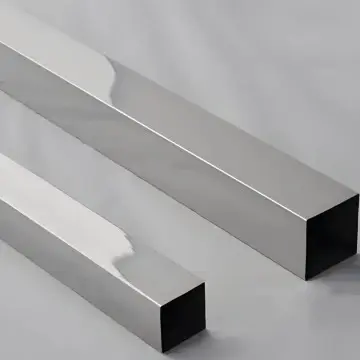

Shape: Different shapes such as round bar, square bar, hexagonal bar etc. are available.

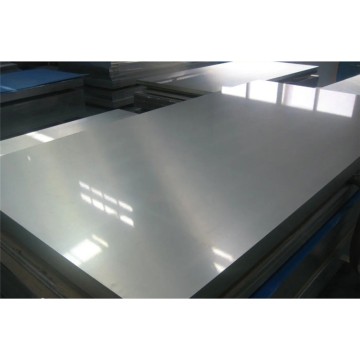

Surface treatment

Surface finish: The surface of stainless steel bars can be polished, pickled, brushed, etc. to improve aesthetics and corrosion resistance.

Coating: Some stainless steel bars may be coated with a protective coating to enhance corrosion resistance.

Advantages

Corrosion resistance: Stainless steel material has excellent corrosion resistance and is suitable for use in harsh environments.

High Strength: Stainless steel bars have high strength and toughness, suitable for bearing greater pressure and load.

Processability: Stainless steel bars are easy to cut, weld and form, suitable for various manufacturing processes.

Application Areas

Construction Industry: used for structural support, railings, stairs, etc.

Manufacturing industry: for machinery parts, tools and equipment.

Automotive industry: used for automotive parts and decorative components.

Chemical Industry: Used in equipment and pipelines, especially in corrosive environments.

Maintenance

Regular Inspection: It is recommended to regularly inspect the surface of the bars to ensure that there is no oxidation and corrosion.

CLEAN: Keep the surface clean to avoid accumulation of dirt and chemicals.

Material Grade

201, 202, 301, 302, 303, 304, 304L, 316, 316L, 321, 308, 308L, 309, 309L, 309S, 309H, 310, 310S , 410, 420, 430, 2205, 2507, 409 etc.

Product Specifications

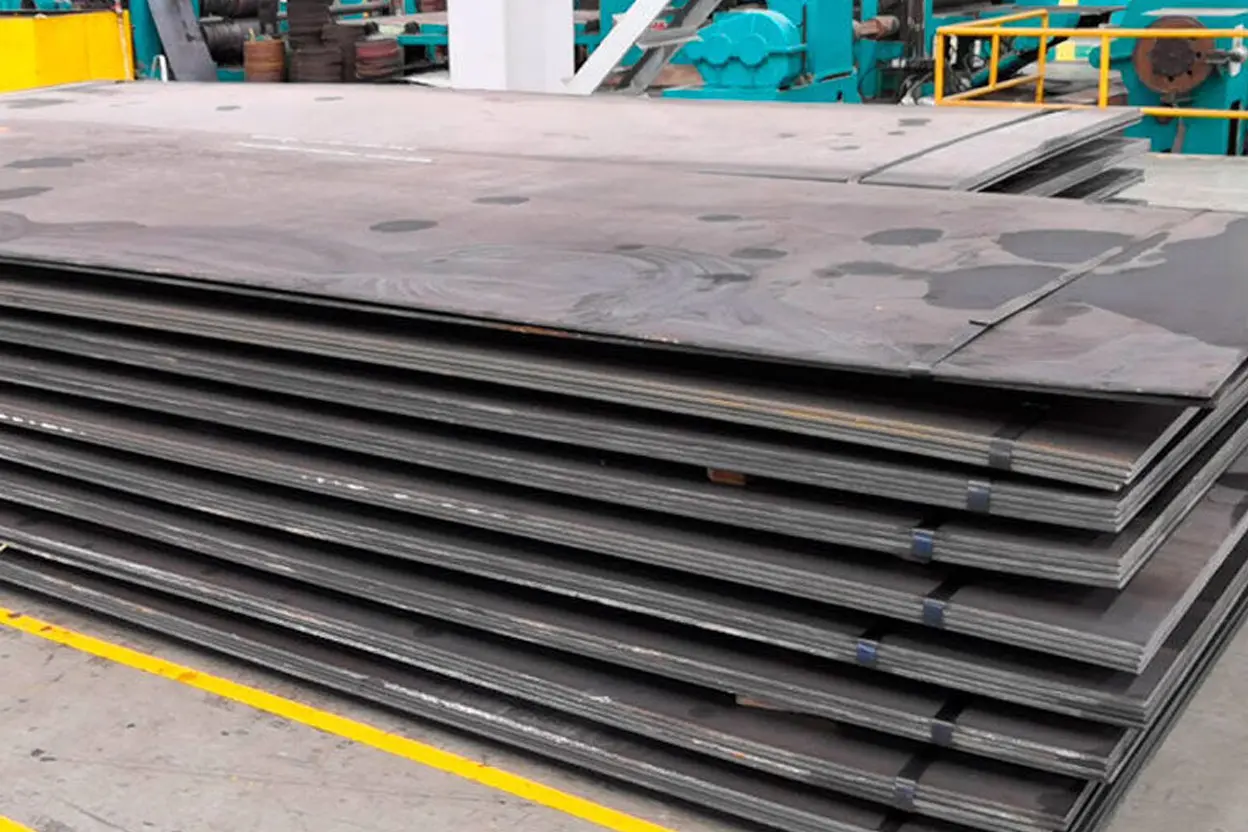

| Hot-rolled black bar | diameter 10-130mm |

| Hot forged black bar | diameter 110-400mm |

| Acid round bar | diameter 5-400mm |

| Cold drawn bright bar | diameter 1-55mm |

| Grinded bright bar | 5-150mm |

| Polishing bright round bar | diameter 5-400mm |

Finish

Black, peeled (K12), cold drawn, turned and polished (H10, H11), precision ground (H9, H8)

Processing Services

Cutting, bending, Titanizing, etc...

Quality Quarantee

Provide photos and videos of production process and accept any third party inspection

Certification

ISO9001, BV, SGS, EN3.1, EN3.2 etc.

Packing

Export sea worthy packing with each bundle tied and protected , Or per clients' requirements.

Application

Chemical, pharmaceutical industry Surgical and medical tools, surgical implants Paper industry digesters, evaporators and handling equipment Petroleum refining equipment Textile industry equipment, textile tubing Scrubbers for environmental control Duct works, feed-water tubes, sewage water filters Heat exchange tubes, ozone generators

transport

010203040506070809