0102030405

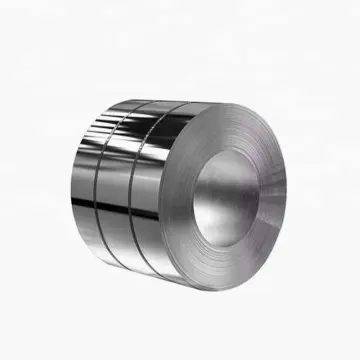

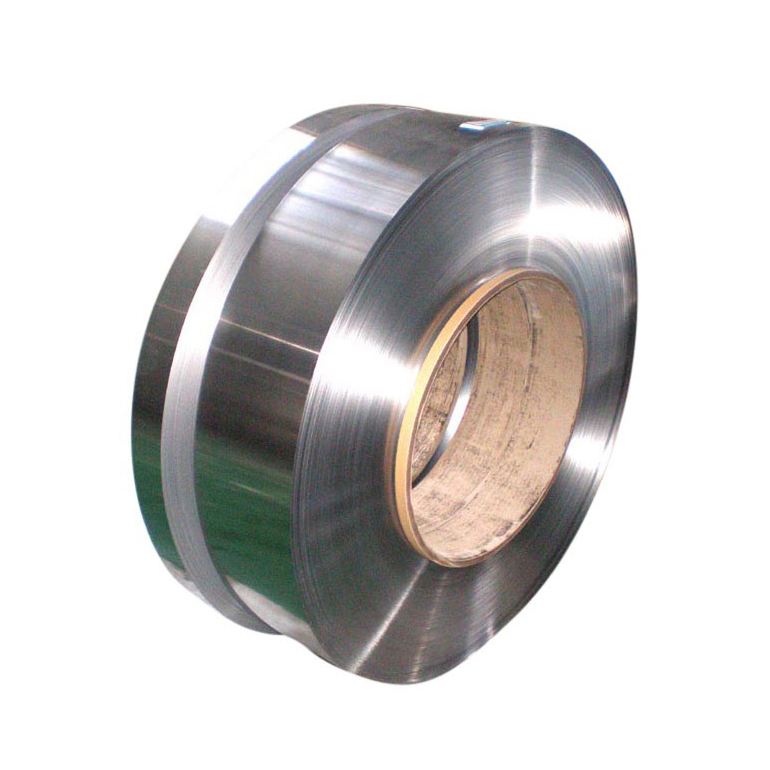

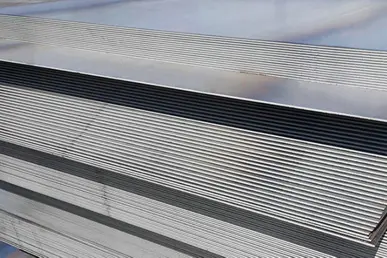

Stainless Steel Strip (0.1mm-5.0mm)

Product Description

Stainless steel strips, like other materials, have physical properties mainly in the following three aspects: thermodynamic properties such as melting point, specific heat capacity, thermal conductivity and linear expansion coefficient, electromagnetic properties such as resistivity, conductivity and magnetic permeability, and mechanical properties such as Young's modulus and rigidity coefficient. These properties are generally considered to be inherent characteristics of stainless steel materials, but they are also affected by factors such as temperature, degree of processing and magnetic field strength. Generally speaking, stainless steel has lower thermal conductivity and higher resistance than pure iron, while properties such as linear expansion coefficient and magnetic permeability vary depending on the crystal structure of the stainless steel itself.

Product Specifications

| Material GRADE | 201, 202, 301, 304, 304L, 316, 316L, 409, 410, 430, 904 |

| Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

| Technique | Hot rolled / cold rolled |

| Raw material source | JISCO, TISCO, BAOSTEEL or as your request |

| Width | 10mm-1250 mm |

| Thickness | 0.1mm-3.0mm |

| Quantity | As your request |

| Surface | 2B, BA, 8K, No.4 No.1, 8K, Mirror finish etc. |

| Product Name | Stainless steel strip |

| Standard | AISI, ASTM, BS, DIN, EN, GB, JIS |

| Grade | C(Max) | Mn(Max) | P(Max) | S(Max) | Si(Max) | Cr | Ni | Mo | N(Max) | Cu/Others |

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.00-20.00 | 8.00-10.50 | - | 0.1 | - |

| 304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.00-20.00 | 8.00-12.00 | - | 0.1 | - |

| 310S | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.00-26.00 | 19.00-22.00 | - | - | - |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - |

| 316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | 0.1 | - |

| 409 | 0.08 | 1 | 0.04 | 0.01 | 1 | 10.50-11.75 | 0.5 | - | - | Ti=6X(C+N) |

| 430 | 0.12 | 1 | 0.04 | 0.03 | 1 | 16.00-18.00 | 0.75 | - | - | - |

| Surface Finished | Characteristics | Application |

| BA | Bright heat treatment after cold rolling. | Ktchen utenstil, Kitchen ware, Architectural purpose. |

| 2B | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to more brighter and smooth surface. | General application medical instruments, Tableware. |

| NO. 1 | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface. | Chemical industry equipment, Industrial tanks. |

| 8K(Mirror) | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh. | Refletor, Mirror, Interior- Exterior decoration for building. |

| Hair Line | Finished by continuous linear polishing. | Architecture industries, Escalators, Kitchen ware, Vehicles. |

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

transport

010203040506070809